A multi-city parcel delivery company in the USA with over 1,200 daily routes and 500–1000 employees aimed to improve its warehouse and last-mile delivery operations. With 30+ years in the logistics industry, the client struggled with growing complexity in package sorting, tracking, and transfers.

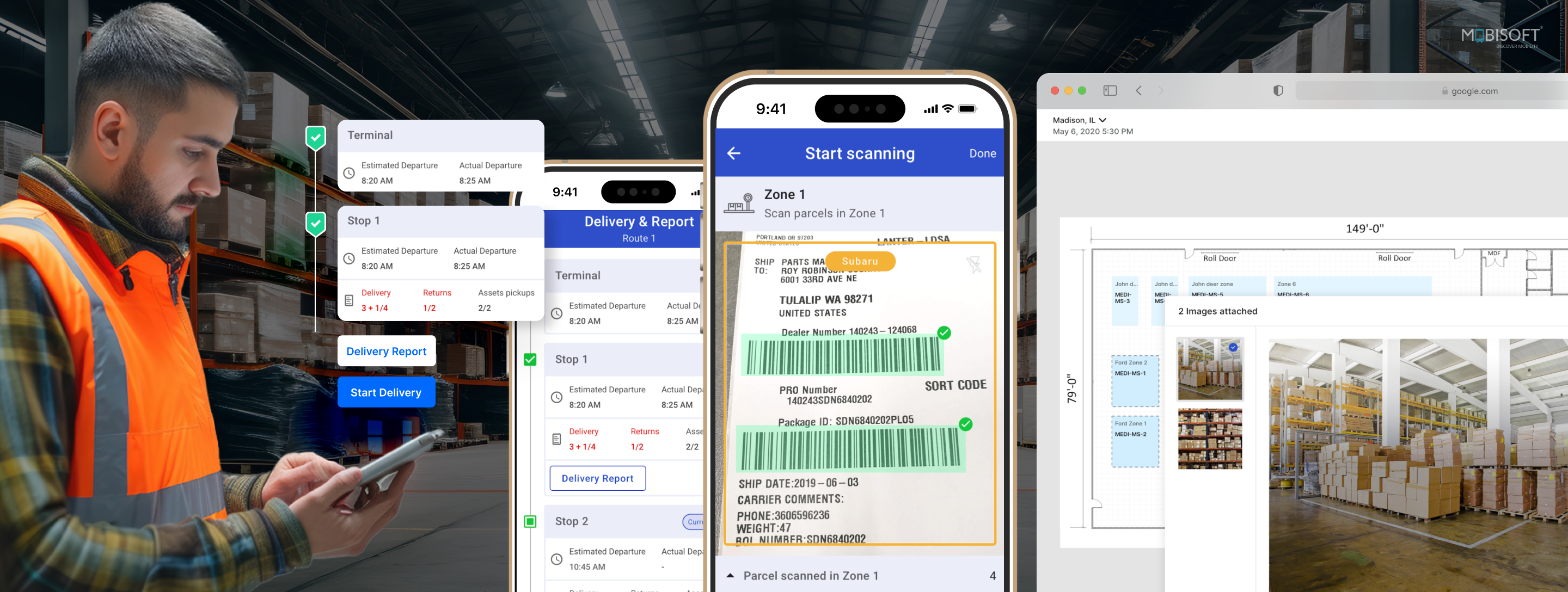

To address this, the company sought a mobile logistics app for delivery built around a scanning-based logistics platform. Our solution digitized package handling across first-mile, transfer, and last-mile operations. The automation improved route compliance, reduced handoff errors, and enhanced delivery speed and traceability across the logistics chain.

The client experienced a series of field-level inefficiencies that directly affected delivery speed, accuracy, and operational control:

The goal: digitize logistics workflows through logistics automation software and scanning-driven processes.

We implemented a scanning-enabled logistics platform to automate the client’s field operations. The platform leveraged mobile-based scanning workflows and real-time possession tracking to support route compliance, package integrity, and faster dispatch readiness. The solution digitized each stage of package movement, from sorting and zone allocation in the warehouse to delivery attempts and return pickups.

Incoming packages were categorized by zones to ensure load sequencing and warehouse automation for delivery efficiency. This early segmentation helps staff manage high volumes efficiently and ensures correct load sequencing for each delivery route.

Staff and drivers use a mobile app with matrix scanning to scan multiple packages at once. This significantly cuts down manual scanning time and speeds up loading and handover cycles.

Each handoff, whether between warehouse staff, drivers, or during cross-docking, is recorded using possession scans. This real-time capture of package custody enables full traceability and ensures accountability at every step.

Before dispatch, every driver’s package set is checked against a dynamically generated route manifest. This ensures route accuracy and prevents misloads or package mismatches.

During loading and unloading, drivers and warehouse teams scan packages to validate compliance, route alignment, and load sequence. This minimizes errors and reduces preparation time before dispatch.

All assigned packages are scanned before the truck exits the warehouse. This confirms complete loading, route compliance, and eliminates the need for manual validation.

During final-mile delivery, each package is scanned, and delivery attempts are logged via the mobile app. Completed deliveries are confirmed with electronic proof of delivery (ePOD), while failed attempts are flagged for follow-up.

Return or reverse logistics packages are scanned, reassigned, and reintegrated into the system. The scanning-based process maintains end-to-end traceability during pickups.

After each trip, a delivery report is auto-generated. It summarizes delivery completions, failed attempts, return pickups, and transit issues, giving the dispatch team complete operational visibility.

OCR is used to scan and match package labels with digital records during sorting and loading. This improves scan accuracy and reduces reliance on manual data entry.

| Metric | Before Implementation | After Implementation |

|---|---|---|

| Package search and sorting time | 8–10 minutes per cycle | 4–6 minutes (up to 40% reduction) |

| Package transfer errors | Frequent | Near zero |

| Vehicle loading time | 45–50 minutes | 10–15 minutes |

| Dispatch readiness | Manual validation | Fully automated scanning |

| Package loss/misplacement | Regular incidents | Fully traceable |

| On-time delivery rate | Approximately 88% | Above 97% |

| Operational throughput | Baseline | Increased by 30–35% |

The scanning-based logistics platform enabled complete digitization of package handling and delivery operations across the client's multi-city logistics network. By introducing zone allocation, matrix scan, possession tracking, and delivery attempt reporting, the company achieved significant gains in speed, accuracy, and transparency. With reduced loading times, higher on-time delivery rates, and full traceability across the delivery chain, the platform successfully eliminated operational blind spots and positioned the client for scalable, data-driven expansion.