A prominent manufacturing company in India, recognized for exporting high-quality products to over 55 countries, faced critical challenges in managing the safety and security of its vast industrial facilities. The company operates round the clock across multiple manufacturing locations. Each facility spans several acres and houses valuable assets including sophisticated machinery, raw materials, and finished products prepared for shipment.

Maintaining security across such expansive premises was essential to protect against theft, unauthorized entry, and potential acts of sabotage. The company required a comprehensive solution that would eliminate the inefficiencies of its existing manual patrolling system and establish a reliable, real-time method of monitoring all security activities across all locations.

The client was dealing with multiple operational and security challenges that exposed the facility to vulnerabilities. These challenges included:

The vast factory premises required constant monitoring across production units, storage spaces, and loading areas.

Overreliance on human guards without technological support such as patrol tracking or geo-fencing can result in security lapses or potential collusion.

Guards relied on manual patrols, which were often inconsistent. Coverage gaps, missed zones, and human errors made it hard to ensure full security.

Supervisors had no way to track guards in real-time. There was little clarity on who was patrolling where, and when.

Most patrol records were handwritten, often incomplete or outdated. It created difficulty in tracking performance, identifying issues, or ensuring accountability.

We deployed a technology-driven security patrolling scanning solution for Bharat wire rope manufacturer. The objective was to enhance the efficiency, reliability, and coverage of their security operations.

A user-friendly mobile application was provided to on-site security personnel. The app displayed scheduled patrol rounds, listed designated checkpoints, and enabled the scanning of QR codes at each checkpoint. Guards could also report incidents on the go. The app ensured patrols were timely, route-based, and data-backed.

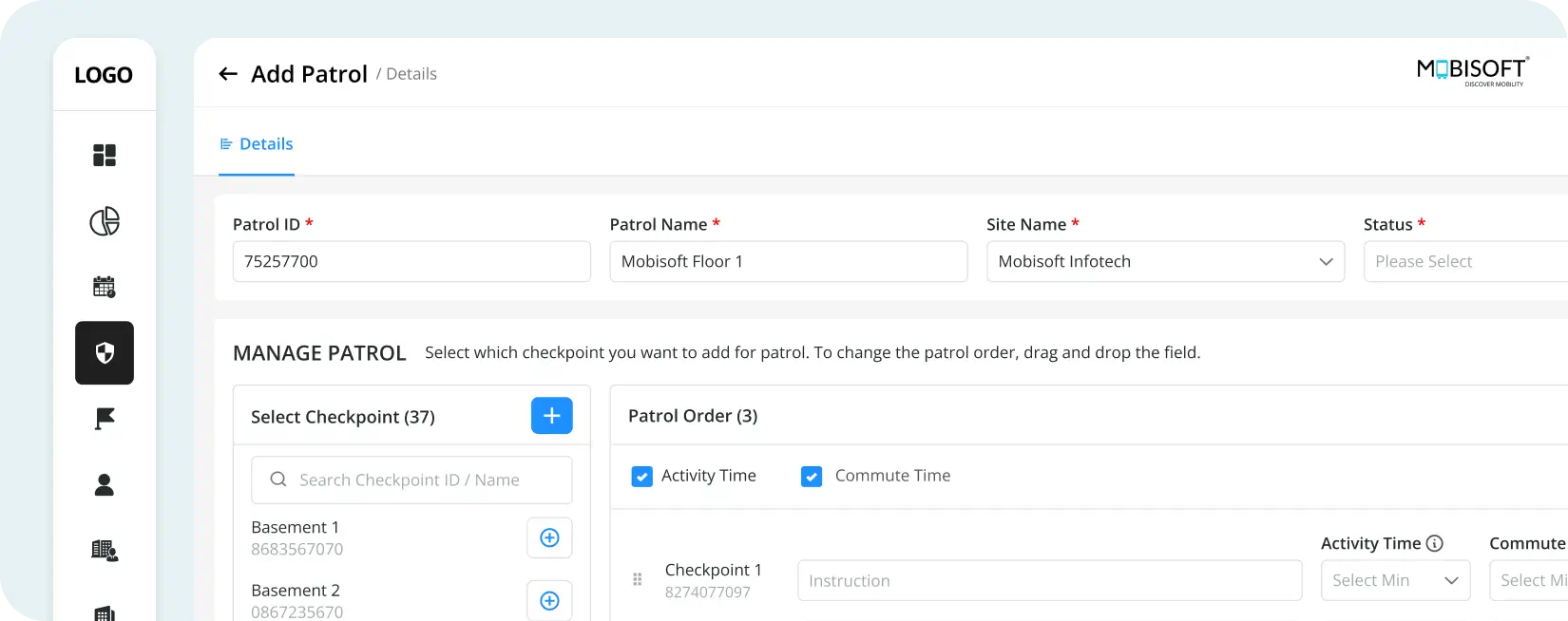

The site manager used a dedicated application to generate and activate QR codes for each checkpoint. The app also allowed them to define patrol rosters, assign specific guards to shifts, and manage security deployment across multiple zones efficiently.

A centralized administrative system enabled the head office team to monitor patrolling activities in real time. The system allowed the scheduling of patrol rounds across different shifts, tracking completion rates, analyzing patrol logs, and generating performance reports.

More than 250 checkpoints were set up across all sites. Each one had a unique QR code with location tracking. Guards scanned these codes during their rounds to confirm they followed the right route and stayed on schedule.

The system automatically compiled detailed reports including missed checkpoints, timestamps for each scan, total rounds completed, and discrepancies in patrol execution. These reports were instantly accessible to the admin team and key stakeholders.

A dynamic dashboard visualized security data through multiple KPIs. Metrics included patrol frequency, missed rounds, duration of each round, and guard performance. This helped managers optimize patrol schedules, improve resource allocation, and ensure tighter control over security operations.

We ensured a smooth and phased implementation process to avoid disruption in day-to-day operations. The key phases included:

A thorough assessment of the facility was conducted to identify high-risk and critical surveillance points. A structured implementation roadmap was created outlining the placement of QR code checkpoints, patrol shift plans, and data flow architecture.

With over 250 checkpoints in the premises, an equivalent number of QR codes were generated and installed at strategic locations of the premises. Each QR code was assigned a unique identifier and geolocation tag to support accurate reporting.

Security personnel, supervisors, and admin staff were trained to use the mobile apps and admin panel. The training ensured effective patrol scheduling, QR code scanning, incident reporting, real-time alerts, and dashboard navigation.

A controlled pilot test was conducted to evaluate system performance, validate scanning accuracy, and ensure usability among the security workforce. Based on feedback, minor adjustments were made to optimize the user experience.

The solution was rolled out across all manufacturing locations. Continuous support was provided during the early adoption phase to help resolve issues quickly and ensure smooth coordination between field staff and the central admin team.

The deployment of the smart security patrolling solution delivered measurable improvements across all key performance areas. Below is a breakdown of the key features used and the associated benefits.

| Feature | Benefit |

|---|---|

| QR Code-Based Patrol System | Accurate validation of rounds, no room for guesswork |

| MobilePatrol App | Allows guards to complete tours, scan checkpoints, and report incidents in real-time |

| Guard Tour System Dashboard | Real-time view of patrol activity, incident trends, and missed tours |

| Customizable Routes & Schedules | Enables unique tour plans for each site and shift |

| Offline Mode Support | Supports checkpoint tracking even in areas with low connectivity |

| Digital Incident Reporting | Allows structured, photo-enabled reporting for faster action |

| Audit Reports | Generates verifiable logs for compliance and management reviews |

| KPI | Before SmartGuard | After SmartGuard |

|---|---|---|

| Patrol Completion Rate | 65% | 99.5% |

| Missed Checkpoints | Frequent | Reduced by 95% |

| Incident Reporting Time | 3-4 hours | < 30 minutes |

| Manual Log Errors | High | Near Zero |

| Audit Compliance | Failing | Fully Compliant |

| Supervisor Visibility | None | Live tracking enabled |

By replacing manual log entries with automated digital processes, the system streamlined security operations with the help of roster management and patrol tour management. It significantly reduced human error with task assignment and scan log times and improved the accuracy of data collection. This digital transformation enhanced operational efficiency and simplified management tasks.

The system provided real-time tracking of security guards during on-ground duty. It allowed the management to monitor patrols and ensure all areas of the premises were adequately covered.

Automated scheduling and tracking of patrols ensured that security personnel follow optimized routes and adhere to schedules. This led to more efficient use of resources and better coverage of the facility.

With the help of strategic checkpoints consisting of QR codes, the entire facility was covered more effectively and the security guard followed precise patrol routes and schedules.

The real-time scanning logs ensured accountability and the system helped in identifying patterns of absenteeism, allowing proactive workforce management.

The system's compatibility with existing mobile devices allowed the security personnel to use their own devices (Bring Your Own Device - BYOD). This reduced the need for additional hardware investment and simplified deployment.

The solution easily scales as the manufacturer grows. It works with different devices and setups, making it simple to add more guards or expand to new sites without starting from scratch.

The detailed reports and KPIs provided valuable insights, enabling the management to optimize patrol operations resulting in more efficient guard utilization.

The successful implementation of the smart security patrolling system helped the manufacturing company modernize its security operations. It enabled complete visibility into guard activity, minimized human error, ensured audit compliance, and improved overall safety standards across its facilities. The solution delivered tangible ROI by increasing efficiency, reducing risks, and creating a secure environment for critical industrial operations.