Every hour, thousands of tons of extracted ore leave remote mining sites, only to face their toughest journey: a multi-hundred-kilometer trek to ports, smelters, or factories. In mining-rich regions like Western Australia or the Southwest U.S., these mining logistics operations often stretch 800 to 1,200 kilometers across rugged terrain.

Yet, despite automation at mine sites, this overland leg still runs into costly slowdowns. A single long-haul truck held up due to mandatory rest breaks, driver fatigue, or handover delays can derail tightly synchronized production schedules, creating ripple effects that delay exports, disrupt contracts, and strain already-thin profit margins.

In this high-stakes environment, driver relay operations, supported by intelligent mining fleet management solutions, are emerging as one of the most effective ways to keep critical resource transportation moving without pause safely, compliantly, and predictably.

For more visibility and control in long-haul operations, explore our Transportation Management System for mining logistics

The Stakes of Mining Logistics

Logistics in the mining industry is the backbone of operational resilience and business performance for mining leaders. When a single truckload of ore doesn’t arrive on time, the consequences cascade:

- Processing schedules are disrupted, delaying production.

- Stockpile congestion creates extra handling costs and demurrage.

- Export targets slip, weakening buyer confidence and contractual footing.

To underline the scale of the challenge:

- In 2022, U.S. mines moved 1.3 billion tons of coal. Trucks carried it to power plants and industrial clients. (EIA)

- In 2023, global iron ore demand passed 2.6 billion metric tons. Steel, infrastructure, and manufacturing drove this growth. (World Steel Association).

Even small inefficiencies in mining transport logistics, a few percent of OPEX, lead to massive losses. According to industry studies, even seemingly small adjustments in freight or inventory strategy can unlock millions in value across a mining operation. (Logistics management for mining companies)

On top of that, mining leaders know from experience - shifting value chains, tighter margin pressure, and global supply shifts mean logistics reliability is no longer optional; it’s mission-critical.

As one logistics executive puts it:

“Today’s logistics leaders must deliver minute-by-minute tracking, cost efficiency, and problem anticipation across global routes.” (Stanton Chase)

So when we say “keeping resources moving,” we’re addressing an urgent leadership agenda: how to drive reliability, cost efficiency, and resilience without excessive incremental capex.

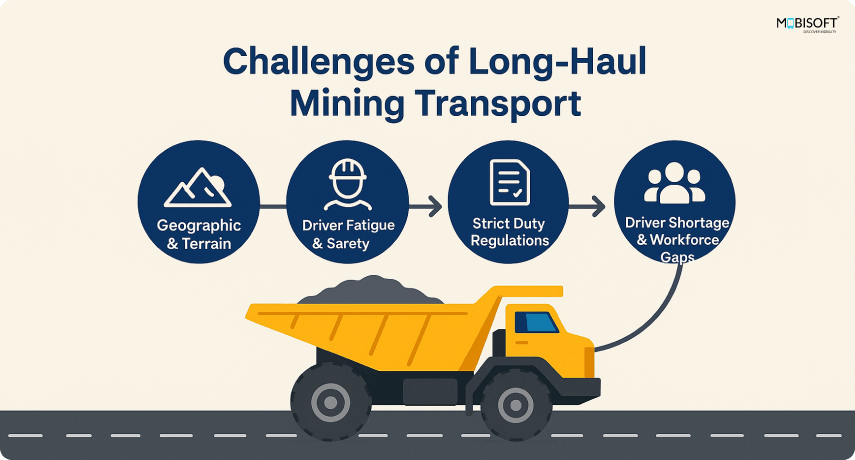

The Challenges of Long-Haul Mining Transport

Getting minerals from remote mines to processing plants is not as simple as sending out a truck. These resource movement in mining routes stretch over thousands of kilometers, through harsh environments and limited infrastructure.

The Simple Reality

Drivers can’t drive forever. Trucks can’t be everywhere. Roads aren’t always ready. And delays cost money.

Now let’s look at what makes long-distance resource transport in mining so difficult:

Driver Fatigue & Safety Risks

Mining corridors demand extended hours behind the wheel, often with minimal nearby infrastructure for rest or recovery. The Federal Motor Carrier Safety Administration (FMCSA) reports that 13% of serious truck crashes involve driver fatigue. In mining, many roads are unpaved and isolated, making it more dangerous.

Fatigue incidents are expensive, with global fleets an estimated $20 billion annually in damages, downtime, and insurance hikes. This makes driver rotation in long-haul mining a necessity for safety and uptime.

Reducing driver fatigue in mining transport is a major benefit of relay operations. Similar methods are already transforming logistics in long-haul trucking, as highlighted in Driver Relay System: The Future of Long Haul Trucking.

Strict Duty Regulations (HOS Compliance)

Most countries limit how a driver operates a truck without rest. In the U.S., Hours-of-Service rules allow driving 11 hours each day. The EU has Regulation (EC) No 561/2006 with strict rules. A 1,000 km mining route should not be completed by a single driver in a shift. Companies must schedule overnight stops or adopt relay driver systems, which add costs and delay shipments but ensure compliance.

Driver Shortage & Workforce Gaps

The driver talent pool is shrinking, especially in long-haul and specialized segments like mining fleet operations:

- The American Trucking Associations estimates a shortfall of 80,000+ drivers in the U.S., expected to double by 2030.

- The International Road Transport Union (IRU) reports 3.6 million unfilled truck driver roles across 36 countries, many in critical supply corridors.

- Mining transport requires certified, terrain-experienced drivers, making recruitment even harder.

Geographic & Terrain Challenges

Mining supply chain logistics face unique terrain pressures. Mining routes aren’t built for comfort. These trucks cross:

- Mountain passes, deserts, and flood-prone regions

- High-altitude or dusty environments that strain engines and brakes

- Remote belts with limited fueling, emergency, or medical support

These terrain and infrastructure limitations introduce unexpected breakdowns, tire failures, and schedule slips, which are difficult to plan for without digital visibility and dispatch management in mining.

Similar workforce optimization strategies are also applied through our Event transportation logistics software.

Relay Operations: The Concept and Its Fit for Mining

In mining transport optimization, delays are operational liabilities. With long distances between extraction points and end-use facilities (processing plants, railheads, or ports), traditional single-driver trucking often fails to meet the performance, safety, and regulatory demands of modern supply chains. This is where driver relay in mining comes in.

What Is a Driver Relay Model?

A relay system breaks long-haul mining corridors into multiple transport segments. At each relay node or interchange yard, a new driver takes over the vehicle while the previous driver rests or returns to the origin.

Think of it as a baton pass in a relay race - only here, the baton is a high-tonnage mining truck carrying copper concentrate, bauxite, coal, or rare earths.

Instead of having one driver stretch over 1,000 km, risking fatigue and non-compliance, a relay setup might involve three drivers operating in safe, pre-assigned legs, ensuring

- Regulatory compliance with Hours-of-Service (HOS) limits

- 24x7 equipment movement, reducing downtime

- Fewer fatigue-related incidents

- Faster round trips and better asset utilization

Why This Fits Mining-Specific Realities

Mining logistics operations are not the same as general logistics. They demand systems that can:

- Handle bulk cargoes with high axle loads

- Operate across remote, underdeveloped haulage operations

- Manage limited roadside amenities and rest areas

- Adapt to mine-to-mill and mine-to-port value chains

Relay driver systems allow logistics teams to stage and rotate drivers based on operational priorities, including:

- Tonnage delivery targets from pit to processing

- Shift alignment with site labor and safety policies

- Reduced layovers at remote loading zones or stockpile yards

Mining Scenario (Illustrative Example)

Let’s say a zinc mine is located 1,100 km from its export port. Traditionally, this journey takes ~28 hours with one driver and mandated rest halts.

With a driver relay in the mining model:

- Three drivers are assigned to 370–400 km legs

- The truck never stops moving, except at swap points

- Total transit time drops to ~20–22 hours

- Driver compliance, vehicle health, and delivery windows improve significantly

Multiply this by a fleet of 80 trucks running 300 days a year, and you start to see material cost savings and output acceleration in mining fleet operations.

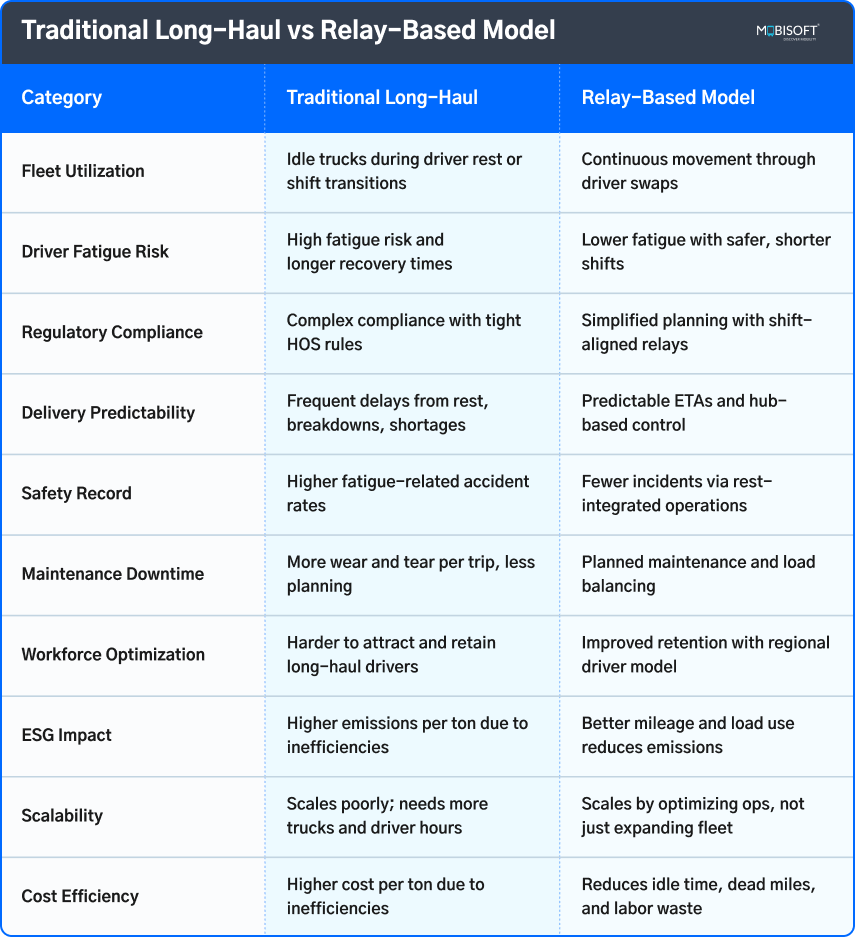

Why Relay Systems Work for Mining

Mining companies have two ways to handle long-distance transport. The standard single-driver model or relay system. Both differ in safety, speed, cost, and daily efficiency. These differences affect operations, budgets, and how fast materials reach their destination.

Relay-based models are proven to improve mining supply chain logistics by reducing fatigue, increasing compliance, and enabling efficient mining logistics at scale.

To support complex supply chains, businesses rely on industry-grade Transportation and logistics solutions.

Technology: The Enabler of Relay Operations

Moving critical resource transportation across long distances isn’t just a matter of manpower and machines it increasingly depends on mining transport optimization and technology-driven coordination. Mining fleets now operate in environments where terrain, weather, driver availability, and compliance windows can shift daily. In such conditions, logistics teams need more than paper-based rosters or spreadsheets.

From Spreadsheets to Smart Systems

Mining fleet management solutions are replacing manual coordination. Leaders use a tech-enabled ecosystem to improve operations, safety, and efficiency. Key tools include:

- Telematics systems - track driver behavior, vehicle health, speed, and fuel use.

- AI-powered routing and dispatch engines - study terrain, weather, and traffic to suggest relay points and shifts.

- Fatigue prediction algorithms that use driving patterns to anticipate rest requirements.

IoT integration to monitor load stability, tire pressure, engine diagnostics, and geofencing.

This is happening now: 70% of logistics firms already use AI solutions, including telematics, to manage fleets more effectively (Business Insider). Meanwhile, the global telematics market for fleet tracking, vehicle utilization in mining, and predictive maintenance is valued at USD 24.3 billion and projected to grow at a 12.9% CAGR through 2034 (Global Market Insights).

Learn more about choosing the right TMS for logistics optimization to upgrade mining fleet operations.

From Automation to Optimization

Relay-based operations introduce complexity but also opportunity. With the right software platform in place, mining companies can orchestrate this model with high precision:

For Fleet Managers & Admins

- The central control panel shows the live status of all relay points, trucks, and drivers.

- Calendar-based shift planners auto-match drivers to time slots and vehicles, to ensure Hours-of-Service (HOS) compliance.

- AI-based recommendations for driver pairing, shift swaps, and route changes based on historical data.

For Drivers (via mobile app)

- Access to their relay schedule, shift location, and fatigue alerts in real time.

- Seamless relay handover logging through app-based check-ins.

- Safety nudges based on telematics, like warnings after sharp turns and extended hours.

These systems reduce uncertainty, improve compliance, and support long-distance resource transport across challenging terrains.

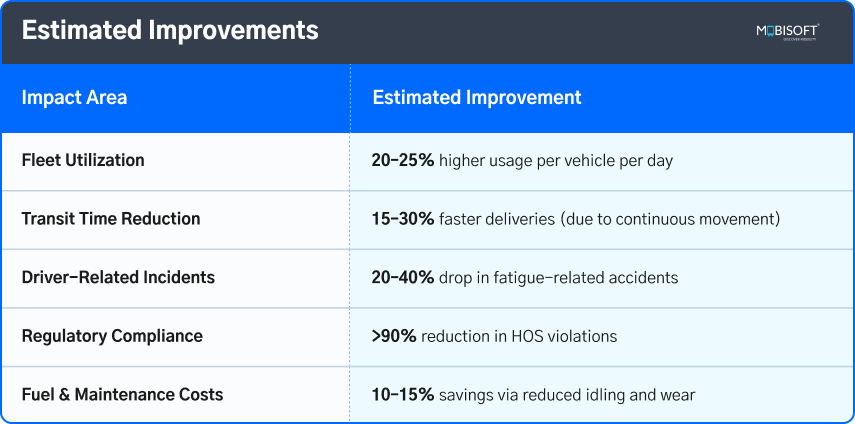

ROI Impact: What Leaders Care About

Mining logistics leaders are measured by cost per ton, equipment uptime, compliance, and delivery performance. Any operational change, relay models, or software automation must be judged by ROI.

ROI of Driver Relay Operations Alone

A structured driver relay operation delivers measurable gains:

Source references: FMCSA, McKinsey Global Mining Review, Fatigue Science, ATA

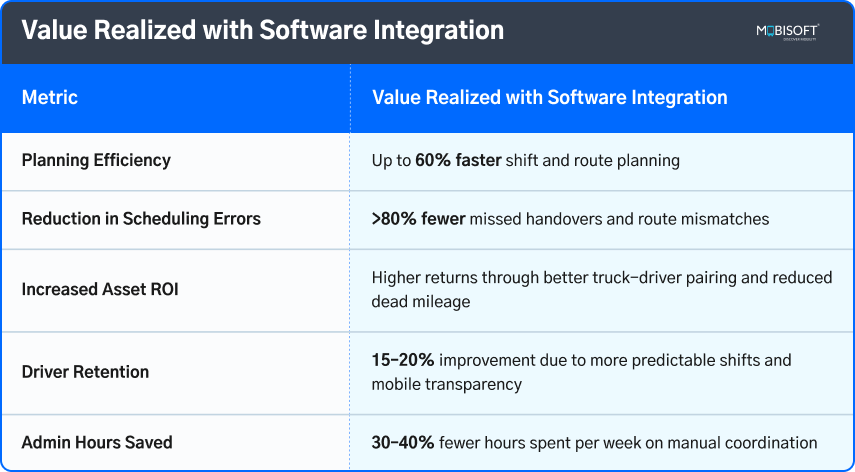

ROI of Software-Enabled Automation

Adding a centralized relay management software system builds an additional layer of efficiency by reducing human error, improving decision speed, and optimizing routes.

Figures shown are illustrative estimates based on industry research (FMCSA, ATA, Fatigue Science, McKinsey) and midpoint assumptions. Actual ROI will vary depending on region, mine-to-port distances, driver availability, and compliance baselines.

Technology-driven automation plays a key role in enhancing logistics efficiency for customer satisfaction.

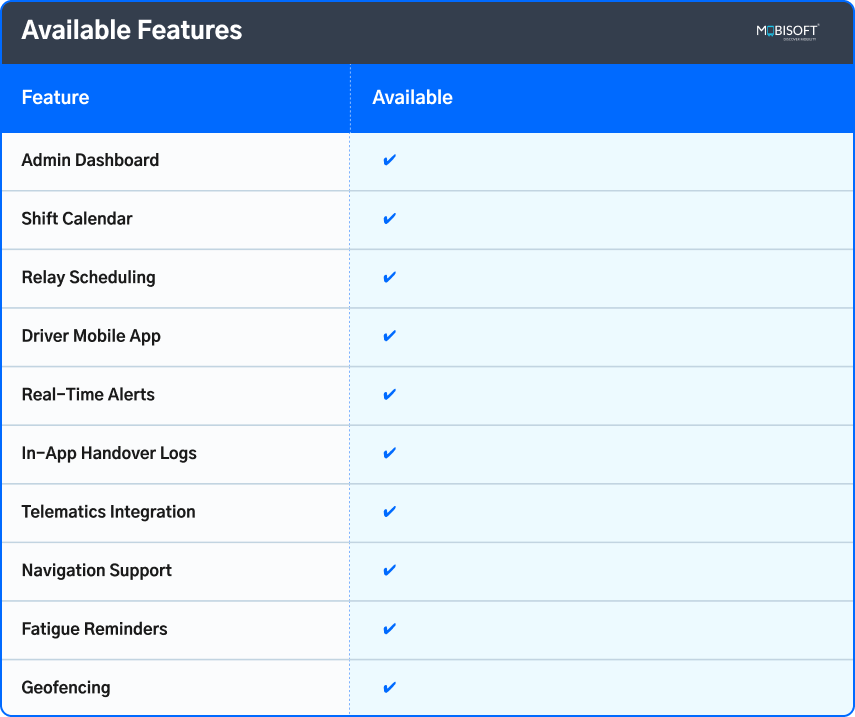

Our Driver Relay Software System

While the relay concept isn’t new, executing it consistently in remote mining site transportation requires the right system.

At Mobisoft Infotech, we’ve developed a Driver Relay Management Software built for industries like mining, metals, and heavy haulage. It supports both fixed relay corridors and adaptive routing models.

Built for Field Realities

Our Driver Relay Management Software is designed with input from logistics heads, relay coordinators, and fleet supervisors across multiple high-load, time-critical sectors. It supports both planned relay corridors and adaptive routing models that adjust to unexpected delays or driver unavailability.

For Admins and Control Rooms

- Relay Manager Dashboard: See all driver-truck pairings, shift durations, and relay handover points in a single interface.

- Calendar-Based Shift Planning: Allocate drivers across relay hubs based on available hours, location, and historical performance.

- Alerts & Compliance Flags: Get notified if a driver’s HOS limit is about to be breached or if a handover is delayed.

- Real-Time Dispatch Panel: Monitor every vehicle's ETA, current leg, and next relay location.

For Drivers in the Field

- Mobile App Access: Drivers get instant updates on relay assignments, next hub location, and current shift status.

- In-App Handover Logs: Digitally confirm relay swaps with geo-stamped signatures and time records.

- Navigation Integration: Turn-by-turn support for reaching relay hubs, even in low-connectivity zones.

- Fatigue Reminders: Optional telematics-based nudges to prompt rest, hydration, or shift wrap-ups.

Optional Integrations

- Telematics platforms for vehicle diagnostics and driver scoring

- HR systems for driver attendance and compliance audits

- Geofencing to auto-log arrival and departure at designated relay hubs

Why It Works

By combining operational visibility with driver-facing simplicity, our system reduces manual coordination, improves compliance, and ensures every leg of the haul moves without disruption.

We don’t just enable driver relay, we make it scalable, auditable, and responsive to the unpredictable nature of mining logistics.

Conclusion: Moving Resources Smarter

Mining transport logistics has the stakes: a late load doesn’t just delay delivery, it disrupts smelters, halts downstream production, and ultimately erodes profit margins. In a sector where operational efficiency is paramount, even small improvements in truck utilization, driver coordination, or delivery timelines can translate into millions of dollars in annual gains.

Relay Is a Strategy

If you're evaluating logistics improvements for the next planning cycle, ask yourself:

- What is your current cost per ton-mile, and what could it be with fewer delays, breakdowns, or fatigue-related incidents?

- How many productive truck hours are lost each week to manual scheduling, idle relay points, or non-compliance?

- How fast could you scale if your existing fleet delivered more, with fewer trucks, fewer headaches, and less admin load?

The truth is, they are financial ones.

This is where technology makes the biggest impact. A driver relay model, when executed manually, offers some gains. But when paired with an intelligent software system, like our relay management platform, the equation shifts entirely:

- No missed handovers due to real-time scheduling and mobile alerts

- No wasted miles thanks to optimized dispatch and routing logic

- No compliance surprises with built-in HOS tracking and fatigue management

- No communication gaps between the control room and drivers across hubs

You’re not just improving transportation. You’re unlocking a system that works harder, thinks faster, and scales without linear cost increases.

Efficient digital systems also highlight the user experience impact on conversion rates for logistics leaders.

Ready to Rethink Your Mining Logistics?

If you’re exploring ways to improve mining supply chain logistics, fleet efficiency, and compliance across long-haul mining routes, we’d be glad to help.

Contact us to learn how our Driver Relay Software System can transform your mining logistics operations.

Whether you're managing iron ore, coal, or critical minerals, our platform is designed to streamline your logistics, making them faster and safer.

June 25, 2025

June 25, 2025