In the high stakes world of enterprise, strategy defines success. Yet, many global players overlook a crucial battlefield: logistics and transportation. For manufacturers, FMCG giants, and diversified conglomerates, moving goods is a perpetual chess match against disruption, carrier failures, regulatory shifts, and global events. Failing to anticipate these moves leads to costly checkmates: missed deliveries, revenue loss, and damaged trust.

Too often, enterprises play blind. They lack the real-time insights and coordinated view needed to counter threats. This blog reveals how to gain a definitive strategic advantage on this chessboard. It's about intelligent foresight and rapid adaptation. A modern transportation management system (TMS) solution is your grandmaster's tool. Beyond optimizing routes, it delivers predictive intelligence to foresee threats, granular visibility to track every piece, and collaborative power to execute winning moves. Master your logistics game. Control your destiny with strong risk mitigation strategies.

Key Risk Challenges Enterprises Face

Even with advanced logistics systems in place, many large enterprises still struggle to manage supply chain risk management (SCRM) effectively. These challenges don’t exist in isolation; they’re interconnected, capable of rippling across entire operations. Many of these challenges can be addressed with robust transportation and logistics solutions designed for complex enterprise needs.

Limited End-to-End Visibility

Most enterprises deal with complex, layered supply chains. They span regions, involve multiple transport modes, and depend heavily on third-party vendors. Without real-time shipment monitoring, tracking becomes a guessing game.

When you can’t see what’s happening in real-time, small delays turn into bigger problems. Missed deadlines, idle trucks, and frustrated customers follow.

And because the warning signs come late or not at all, teams often react instead of respond. This lack of visibility takes away the agility needed to adjust routes, update partners, or take action before issues escalate.

Compliance Complexities

Global operations navigate a maze of regulatory compliance in logistics, from customs declarations to international certifications. Each country and sector (especially pharma or chemicals) comes with changing standards. When compliance is handled manually, errors are inevitable.

When compliance management is handled manually or through disconnected systems, errors are common. A single missing document can stall an entire shipment. Fines, legal consequences, and reputational damage follow.

In addition, firms in highly regulated industries such as pharma, food, or chemicals carry even higher risks, where non compliance can compromise safety as well as public trust.

Carrier and SLA Management Issues

Few firms are dependent on one logistics company. Rather, they have dozens, if not hundreds, of carriers moving products along different routes and modes. This raises the question: how to guarantee each partner performs consistently against the agreed Service Level Agreements (SLAs)?

Manual tracking of delivery times, proof of delivery (POD), and contract compliance becomes impossible at high volumes. Upon SLA breaches, the downstream consequence is instantaneous, customer complaints, production line deceleration, and increased transport expense from rebooking or penalties. It's hard to hold carriers accountable without a dependable transportation management system (TMS) to track carrier performance in real-time.

Inability to Predict Risk Proactively

While most businesses gather enormous amounts of logistics data, few are successful in turning the data into useful insights. They lack the tools to analyze historical patterns or detect early warning signs that signal disruptions, weather-related problems, traffic congestion, or labor shortages, to add only a few.

This implies most companies will react. When trouble hits, attention turns to damage control rather than proactive mitigation. The outcome? Rapid fire decisions, suboptimal workarounds, and lost chances to contain costs or safeguard service levels.

For deeper insight into how mobile innovations enhance foresight, the Development Of Smartphone Application: Impacts On Logistics And Transportation Industry highlights how digital transformation drives logistics intelligence.

Poor Communication During Incidents

When there is a disruption, clear and rapid communication is required. But most companies are still working with siloed tools, emails, phone calls, and spreadsheets that slow down incident response. Critical stakeholders in shipping, procurement, customer service, and third-party carriers are rarely aligned with each other, and this leads to miscommunication and conflicting behavior.

Slow or miscommunication is a source of downtime. It is progressively more challenging to reroute shipments, inform customers, or make real-time inventory planning. Worse, the lack of a shared understanding of the issue can undermine customer and logistics partner relationships.

In an age where customers expect transparency and promptness of communication, such failures can be more than a cost to the bottom line, they can destroy brand trust and long term loyalty.

How a TMS Strengthens Risk Management

A new age transportation management system (TMS) helps enterprises build smarter, more resilient logistics operations aligned with enterprise risk management (ERM) principles.

Here’s how:

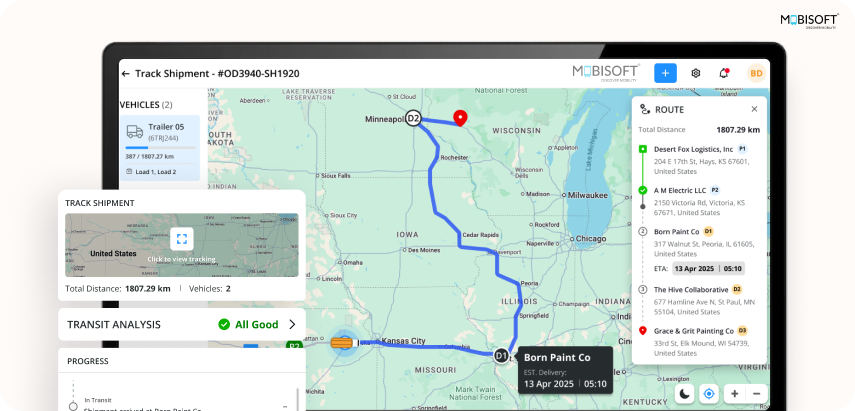

Real-Time Shipment Visibility & Alerts

A TMS offers a live view of your supply chain. It tracks shipments at every stage, from dispatch to delivery, across transport modes and geographies.

When a shipment is delayed or takes a wrong turn, the system immediately notifies key stakeholders. This gives teams the time and context to respond quickly, reroute if needed, and keep customers informed.

These alerts are not just time based but context aware; they can notify you of potential compliance misses, late arrivals, or even driver idle time.

Compliance & Documentation Management

Managing cross-border transportation means dealing with customs documents, transport permits, invoices, and various certificates. A modern TMS digitizes and automates these workflows.

It ensures that all necessary paperwork is complete and compliant, reducing the risk of regulatory penalties and shipment holds. Built-in templates, reminders, and auto verification features help avoid costly documentation errors.

It also aligns with enterprise-grade standards like SOC 2, ISO 27001, and GDPR, ensuring that your data is safe, auditable, and policy compliant. It also enables audits and internal verifications with digital traces and easy retrieval in line with ISO 31000:2009 and Supply Chain Risk Management Integration guidelines.

Contract & SLA Enforcement

TMS solutions track every logistics partner against pre-determined service level agreements. From transit time to pick up accuracy or condition of goods upon delivery, the system alerts to deviations in real-time.

This allows logistics managers to hold carriers accountable, settle disputes with fact based evidence, and renegotiate contracts where needed. This creates stronger, performance based relationships with your logistics providers in the long run and boosts supply chain resilience.

Advanced Analytics & Predictive Insights

The real power of a TMS is in its data features, collecting and processing past and real-time data to predict potential problems that may arise in the future.

For example, if a specific route is consistently resulting in delays and if a supplier consistently has compliance issues, the system indicates these patterns. Predictive analytics also considers external threats like bad weather, labor conflicts, or port congestion. This is where innovations like AI in Supply Chain Risk Assessment come into play, enhancing the ability to detect early warning signs and mitigate risks proactively.

Firms can then model out of sequence schedules, pre emptively divert shipments, or insert extra buffer time, long before a risk has any chance to become a problem.

Collaborative Platform for Stakeholders

During emergencies, every minute counts. A modern TMS brings internal employees, outside carriers, and even customers under one roof.

All interested parties share the same real-time information, audit trails, and shipment status. Such access promotes faster decision-making and reduces finger-pointing. Automated workflows, secondly, ensure that the correct interested parties are alerted and progress through a defined process to resolve.

Benefits of Risk-Aware Logistics for Enterprises

Forward thinking and risk averse logistics are more than damage prevention. It's about creating a responsive, high performing logistics organization that fuels enterprise growth. As organizations can anticipate, manage, and recover from disruptions, the paybacks are realized in operations, finance, and customer experience.

Reduced Operational Downtime

Logistics downtime can shut down entire operations, whether it's tardy inbound materials or tardy outbound shipments. A contemporary transportation management system (TMS) reduces the risk of this happening by tracking shipment progress around the clock and sending real-time shipment monitoring alerts on the possibility of delays, route deviations, or congestion.

By having automated workflows and early alerts, teams can respond quickly. Alternate routes or carriers can be triggered, resources can be redirected, and customers can be alerted before disruptions spiral out of control. This ability to respond early recovers lost time, prevents cascading issues across the supply chain, and maintains service continuity.

Lower Compliance Violations

Regulatory compliance in logistics is the most underestimated but dollar impactful logistics risk. Non-compliance typically results in delayed shipments, border rejection, or monetary fines. An awareness-driven TMS automates the collection, storage, and distribution of key compliance documents, customs forms, licenses, certifications, and route permits.

Most importantly, it keeps these documents up to date and in compliance with the exact specifications of both the origin and destination of each shipment. This prevents human errors, prevents last minute documentation errors, and maintains businesses in compliance in every operating geography. It also enables audits and internal verifications with digital traces and easy retrieval in line with ISO 31000 risk management guidelines.

Improved Strategic Decisions

In logistics, every decision counts, whether deciding the best route, deciding on a good carrier, or deciding on inventory. A risk conscious TMS provides organizations with information to make such decisions with confidence.

Through carrier performance monitoring, delay pattern detection, and high risk lane detection, teams can make smart, informed choices. This helps achieve the best blend of cost, speed, and reliability, making logistics a top business performance driver. These data driven decisions align with modern enterprise risk management (ERM) practices.

For enterprises wondering where to begin or how to assess the right platform, read this comprehensive breakdown on Why Enterprises Need a Scalable, Secure, and Customizable TMS?

Greater Customer Satisfaction

Customers today expect more than fast delivery. They want updates, visibility, and clear communication. When these needs are met, it builds trust and improves the overall experience.

A modern TMS enables real-time shipment monitoring, accurate delivery estimates, and quick resolution of issues. This keeps customers informed and reassured, even during disruptions. Consistent, transparent service goes a long way in earning repeat business and strengthening brand loyalty.

Enhanced Agility and Resilience

Supply chain disruptions come in many forms, weather, strikes, and system failures. The challenge isn’t avoiding them, but responding fast and staying.

With live data and predictive tools, a TMS gives your team the agility to adapt. Reroute shipments, shift inventory, or switch carriers, all without delays. This kind of flexibility shortens recovery time and builds lasting supply chain resilience.

Conclusion: Building Stronger, Smarter Logistics

Businesses are confronted with higher logistics risk now than ever, constrained visibility, regulatory compliance, increasing cost, and unchecked disruptions. These risks slow down operations, increase costs, and affect customer satisfaction.

A contemporary Transportation Management System addresses these problems head-on. With real-time shipment monitoring, workflows are automated, and increased insight, logistics staff are in command and operate with confidence.

By combining the right tools, companies build a more resilient, more agile supply chain, one that keeps service levels, operations running, and customers happy.

Wish to improve how you manage logistics risk?Arrange your demo and see how a TMS can power greater, faster decisions for your business.

May 27, 2025

May 27, 2025