We've all moved past simply finding things. Modern smart asset tracking is really about understanding an asset's story, from its movement and health to its role in your operations. And let's be honest, as businesses expand, their supply chains become vast networks that span multiple partners and geographies.

So what comes next? A new wave is building. It integrates IoT sensors, AI, digital twins, and multi-network connectivity through the combination of AI, IoT sensors, and digital twins. These advancements make your system feel almost alive, like a self-learning ecosystem that strengthens asset visibility and enhances decision-making. This article explores that generation, from the basic tech to the intelligent automation and predictive insights that truly change how we work.

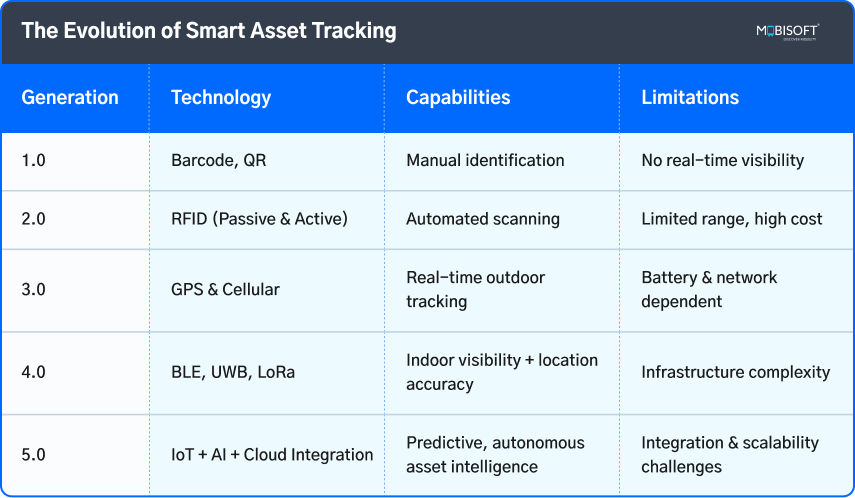

The Evolution of Smart Asset Tracking

Let’s look at how the landscape has evolved:

Each stage moved closer to real-time asset tracking decision-making and data-driven asset management control. Now, we’re entering an era where assets themselves communicate, providing not just location, but context, temperature, vibration, tampering, and usage patterns supported by asset tracking analytics and intelligent modelling.

Explore how modern connectivity accelerates intelligent tracking with our IoT development services.

Core Technologies Powering Modern Smart Asset Tracking

RFID & NFC

RFID, or Radio Frequency Identification, is still everywhere, and for good reason. It lets you identify tagged assets quickly, without even needing a direct line of sight. It just works.

- Use Case: Warehouse inventory, returnable packaging, tool tracking.

- Advantage: Bulk scanning, reliable indoors.

- Next-gen Shift: Integration with BLE and AI for condition-based tracking.

GPS & Cellular

The foundation of mobile asset tracking visibility. With 4G LTE, NB-IoT, and now 5G, GPS asset tracking has become more accurate and energy efficient.

- Use Case: Fleet assets, outdoor containers, construction machinery.

- Next-gen Shift: Edge analytics in GPS devices and eSIM-based global connectivity.

Bluetooth Low Energy (BLE) & Ultra-Wideband (UWB)

These have transformed indoor tracking. BLE tags combined with gateways enable real-time asset tracking within warehouses or hospitals.

- Use Case: Pallet tracking, hospital equipment, workforce safety.

- Next-gen Shift: BLE Mesh + AI triangulation for 1–3m accuracy.

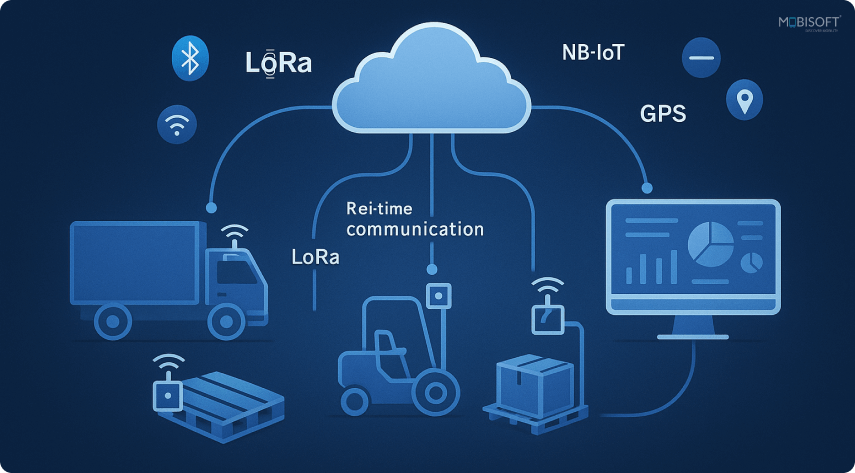

LoRaWAN & Private 5G

LoRa is crucial for tough industrial yards and mining sites. It offers long-range tracking without guzzling power. But then private 5G networks come in, taking things to another level entirely.

- Use Case: Large campuses, seaports, logistics hubs.

- Next-gen Shift: Network slicing and latency optimization for autonomous systems.

Hybrid Tracking Systems

Future-ready tracking is a team effort. Think RFID asset tracking and BLE working together for area awareness, or BLE and GPS asset tracking joining forces to bridge the gap between inside and outside. It’s this kind of practical combination that delivers real results.

- Use Case: Cold chain, returnable logistics, and manufacturing flow monitoring.

- Next-gen Shift: Unified cloud dashboard integrating all signal layers.

Strengthen your tech stack with advanced insights powered by AI-driven intelligence.

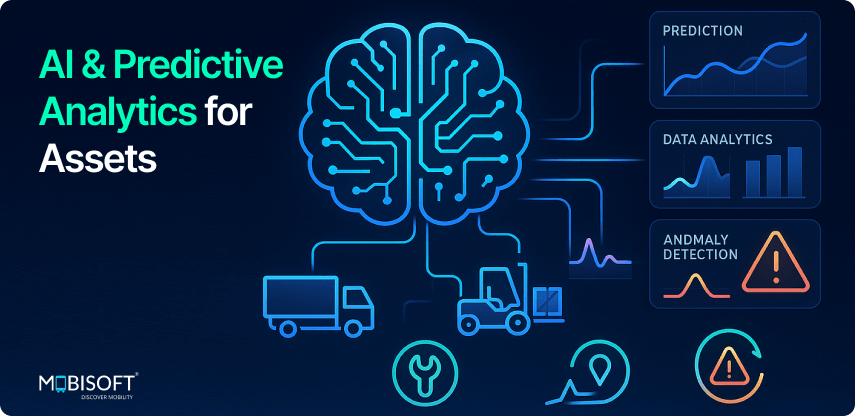

Intelligent Data Layer: AI, ML & Advanced Asset Tracking Analytics

Tracking data is only valuable when it turns into insight. Modern systems use AI and ML models to analyze:

- Utilization rates: This means pinpointing idle assets so you can put them back to work efficiently, improving asset utilization optimization.

- Predictive maintenance: It involves spotting unusual patterns in temperature, vibration, or movement before they become real problems, supporting predictive analytics for asset tracking.

- Geofencing alerts: Geofencing alerts notify you the moment an asset moves outside its permitted area.

- Lifecycle analytics: This helps you decide the perfect time to replace an asset by carefully examining its actual usage patterns over time.

Integration: ERP, WMS, and IoT Platforms

To create true visibility, asset tracking must connect with enterprise systems:

- ERP (SAP, Oracle, Microsoft Dynamics): For asset cost, depreciation, and transfer tracking.

- WMS/TMS: Your Warehouse and Transport Management Systems manage all the crucial details of the process, from movement and dispatch to proof of delivery.

- IoT Platforms: These are developed particularly for managing and storing sensor data and telemetry information in real-time.

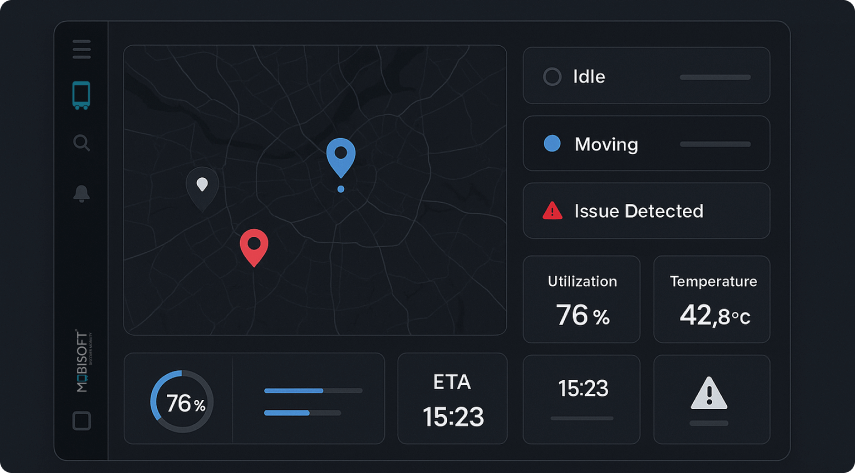

Linking OPC-UA, REST, or MQTT into a system of APIs and middleware is important. It greatly reduces the effort of syncing all live data. They cut down on tedious manual entry and, even better, they power those live dashboards that give you an immediate view of your operations.

This connectivity transforms tracking from operational to strategic, helping CFOs see asset ROI and COOs monitor utilization efficiency. Build a connected ecosystem with scalable custom asset tracking software.

Practical Implementation Strategy

You can't just jump in, roll out an asset tracking system without a clear, structured plan instead:

Step 1: Define Objectives

Define the aim. Are you primarily solving for visibility, or is security your top concern? Maybe you need to meet strict compliance rules, or perhaps your main goal is pure operational optimization. Each of these goals asks for different technologies and requires a specific level of data detail. Getting this right at the start saves so much trouble later, especially when building smart asset tracking capabilities.

Step 2: Conduct a Pilot

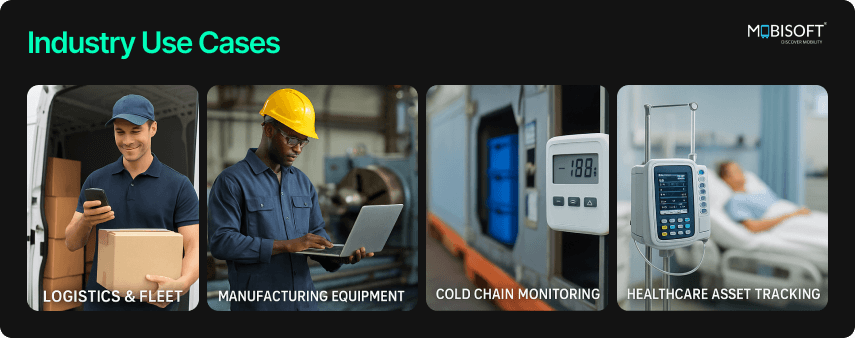

Choose a single warehouse, one fleet of vehicles, or a specific production area. This small-scale test is your chance to validate everything. Check the wireless coverage, see if the signal strength holds up, and make sure the software actually feels usable for your team, especially in environments that may later need healthcare asset tracking, construction asset tracking, or cold chain asset tracking in full deployment.

Step 3: Integrate Data Flows

After the pilot proves itself, it's time to integrate the data flows. This means connecting your new tracking layer to the systems you already use, like your ERP or WMS. The aim is a smooth sync of master data and daily transactions, creating a single source of truth that supports data-driven asset management.

Step 4: Scale & Automate

Once that seems steady, you can scale up with confidence and bring in automation across the company. This is when you set up those automated alerts, roll out live dashboards for all staff, and switch on the predictive models that give you a real advantage, aligning with modern predictive analytics for asset tracking.

Step 5: Measure ROI

Quantify benefits:

- Reduced loss or theft

- Improved asset utilization optimization

- Lower manual tracking hours

- Enhanced audit accuracy

Accelerate implementation maturity with our digital transformation services.

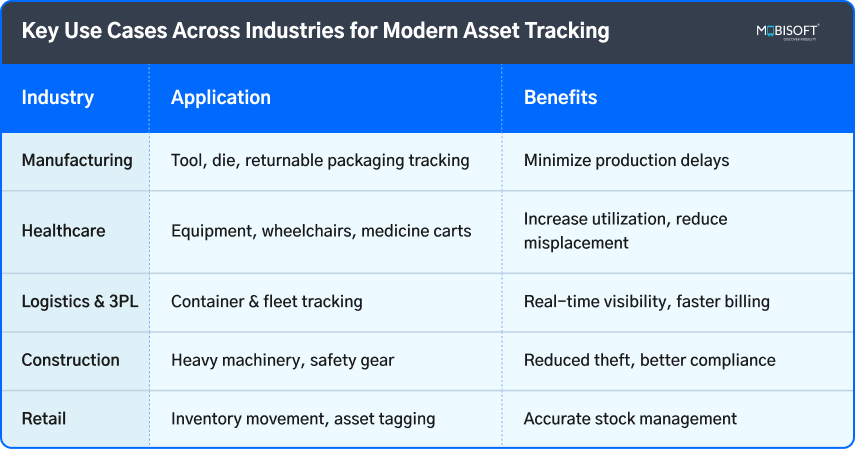

Key Use Cases Across Industries for Modern Asset Tracking

Each use case can evolve from simple location tracking to predictive visibility, where the system forecasts shortages, asset failures, or movement patterns automatically. This is also where solutions such as RFID asset tracking or other sensor technologies become more impactful. See how mobility innovation shapes modern operations with IoT in automotive industry.

Challenges in Modern Deployments of Asset Tracking

The advantages are obvious, but let's be honest, a smooth rollout has its own set of obstacles. The major ones are:

- Interference & Coverage: Metals and liquids can play havoc with RFID and BLE signals.

- Power Management: GPS devices consume more energy.

- Data Overload: Millions of data points need intelligent filtering that aligns with modern asset tracking analytics.

- Change Management: Workforce training and process alignment.

- Integration Costs: ERP and legacy system compatibility.

The good news is that modern systems fight back with some clever techniques. They use AI in asset tracking to dynamically clean up and optimize signals. They use energy-harvesting tags that gather power from their surroundings, so they never need a battery change. And they rely on cloud-native middleware, which works as a universal translator to blend everything into one unified system.

The Shift Toward Predictive & Autonomous Asset Management

We're now entering a new chapter where the real value isn't in tracking, but in thinking. The focus is squarely on intelligence.

- AI models forecast when an asset might fail or go missing, bringing deeper insights powered by AI in asset tracking

- IoT sensors constantly monitor surroundings, picking up on subtle environmental changes like shifts in humidity or any signs of tampering.

- Digital twins replicate entire operations virtually, enabling scenario simulation and remote management, forming a strong foundation for digital twin asset tracking.

Imagine a manufacturer looking at a live 3D digital replica of their entire operation. They can see every pallet, every forklift, every bin of raw material. Digital twins use all that integrated data to actually predict a material shortage before it ever happens. Improve real-time operational control with a unified transportation management system.

Data Security and Compliance in Large-Scale Asset Tracking

When tracking stretches across borders, data security and regulatory compliance move from checklist items to absolute necessities. This isn't just a technicality anymore:

- Encryption: It must guard your data during transmission and while it's stored.

- Access Control: Tighten permissions, managing through role-based permissions so people only see what they must.

- Data Localization: Data localization requires careful attention, ensuring you respect country-specific laws like GDPR, SOC 2, or ISO 27001.

- Audit Trails: Detailed audit trails are crucial for tracing every asset movement and data change.

Modern platforms, think of tools like FleetNXT TMS or AssetCues, are built for this. They often provide on-premise deployment options for businesses that need them. Another feature is that they ensure full compliance by operating within secure cloud environments.

Future Outlook: Where Asset Tracking Is Headed

The next decade will redefine asset visibility. Expect these emerging trends:

- 5G-enabled microtrackers: Microtrackers will offer real-time, sub-meter accuracy almost anywhere.

- Energy-harvesting sensors: These sensors will eliminate battery replacements, making maintenance a forgotten chore.

- Blockchain-based audit trails: These are the asset's entire history, unchangeable and therefore reliable.

- Edge AI: It will bring decision-making directly to the devices, improving latency.

- Sustainability dashboards: Sustainability dashboards will begin tracking the carbon footprint of every single asset movement.

Asset tracking will act like the central nervous system for digital enterprises. It connects your people, your machines, and your materials into one intelligent, cohesive ecosystem. Solutions such as IoT asset tracking, RFID asset tracking, and Bluetooth asset tracking will continue shaping how businesses manage high-value items, whether in facilities or across global supply chains.

Summary & Next Steps for Implementing Intelligent Asset Tracking

So, to pull it all together, the progression of asset tracking is quickly moving past simply monitoring location and toward genuine operational intelligence. Your choice of technology directly influences operation. It affects how nimbly and efficiently your organization can function, adapt, and ultimately grow.

Next Steps:

- Start by assessing your current maturity. Is your process mostly manual, semi-automated, or already intelligent?

- Then, select a single pilot area where you can demonstrate a clear return on investment.

- Design a technology mix that fits your unique environment.

- Integrate it thoughtfully, connecting it to your existing ERP, WMS, and IoT dashboards.

- Finally, scale with purpose, gradually moving toward predictive and autonomous tracking capabilities supported by asset tracking analytics and data-driven asset management.

By following this path, your organization can unlock greater efficiency, significantly lower operational losses, and gain asset intelligence you can actually use. The goal now is to move beyond just tracking assets. It's time to truly understand them. Explore how data intelligence strengthens mobility networks with machine learning in micro-mobility.

Key Takeaways for High-Impact Smart Asset Tracking Deployments

- Modern tracking tools uncover an asset’s full story, giving teams clearer insight into usage patterns and early hints of stress through machine learning asset tracking capabilities.

- AI turns dense telemetry into practical guidance, helping organizations act before small irregularities become costly issues.

- Blended tracking networks keep assets visible across warehouses, yards, and long routes, supporting GPS asset tracking, satellite asset tracking, and more.

- Integrations with ERP and WMS systems build one reliable thread of data, reducing manual work and tightening financial accuracy.

- Careful pilots reveal coverage gaps and workflow hurdles, allowing teams to correct issues before scaling across the enterprise.

- Digital twins offer a visual model of operations, helping leaders test decisions and understand bottlenecks without disrupting work.

- Strong governance around data access, encryption, and compliance keeps tracking deployments safe and dependable across regions.

FAQs: Understanding Modern Asset Tracking Systems

How are companies using asset tracking beyond simple location updates?

Modern systems help teams study an asset’s entire journey, from daily usage patterns to signs of strain that often go unnoticed. Many organizations now rely on these insights to adjust scheduling, rebalance equipment loads, or retire items earlier than planned. This creates a smoother decision process that feels surprisingly intuitive for large operations, especially in areas like asset tracking for logistics, cold chain asset tracking, healthcare asset tracking, construction asset tracking, and asset tracking in manufacturing.

What makes AI-driven tracking useful for operations teams?

AI combs through dense telemetry data and highlights issues long before people spot them. It studies temperature spikes, unusual vibration, or irregular movement and presents them in a way that feels clear rather than overwhelming. Teams gain early warnings, tighter control, and a level of operational calm that comes from knowing problems are flagged before they escalate.

How do hybrid tracking systems help complex facilities?

A blended setup combines multiple signals, allowing indoor and outdoor assets to stay visible without interruption. Companies often pair BLE and RFID for local awareness, then rely on GPS once items move out of the facility. The handoff feels seamless, giving managers consistent context across long routes and crowded yards.

Why do enterprises connect asset trackers to ERP or WMS platforms?

These integrations build a single thread of truth that ties financial, operational, and movement data together. Every update flows into the systems people already use, reducing manual entries and routine errors. Leaders get cleaner reports, quicker reconciliations, and policies that actually reflect what is happening on the floor.

What challenges appear during large-scale deployments?

Wireless problems, battery issues, and too much data often cause unexpected problems when companies first use new systems. Teams also need time to change how they work and rely on the new information. With slow introduction and careful adjustments, companies reach a point where the system seems reliable instead of burdensome.

How do digital twins support smarter planning

A digital twin creates a live model of operations showing the movement, state, and actions of assets in one visual space. Leaders can try out different plans, spot bottlenecks, or check capacity plans without messing up the real work area.

Why are security and compliance becoming central to asset tracking?

Operations across borders have stricter data rules, so companies pay more attention to data protection, who can access it, and where it's stored. New platforms are built to meet these needs with built-in checking and control features. This keeps sensitive movement data safe while keeping operations running.

November 21, 2025

November 21, 2025