Digital manufacturing proves its value quickly within a single facility. The environment is bounded, leadership lines are clear, and operational nuances are widely understood. Early gains create confidence that expansion will be straightforward.

Complexity intensifies when deployment spans multiple plants in multi-plant manufacturing environments. Identical systems encounter different production rhythms, equipment histories, and reporting conventions across multi-site manufacturing operations. A downtime threshold interpreted as critical in one site may be considered routine in another. Escalation protocols vary. Performance metrics carry uneven weight. These differences are rarely visible during pilot success, yet they determine the stability of scaled execution.

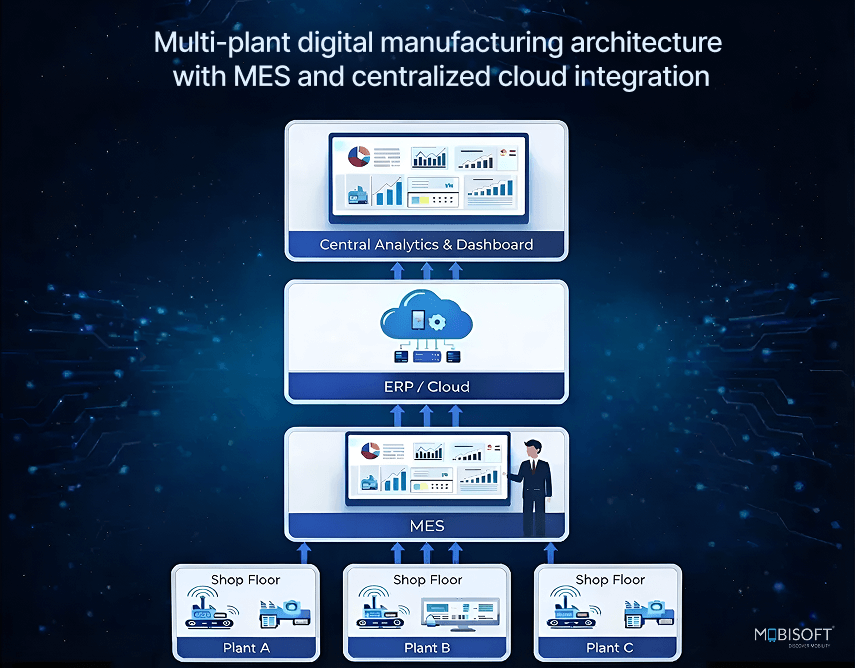

Multi-plant growth, therefore, exposes structural misalignment rather than technological weakness. Digital capability does not falter because tools lack sophistication. It falters when coordination mechanisms remain local while systems become enterprise-wide. Scaling without disruption requires disciplined synchronization across plants so that expansion reinforces operational stability instead of fragmenting it while scaling manufacturing operations.

To explore how enterprise-wide transformation frameworks enable stable scale across plants, read more about our digital transformation services.

Process Drift in Multi-Plant Networks

Most scaling plans assume plants under the same brand are similar enough to adopt identical digital tools within broader digital transformation in manufacturing strategies. That assumption is almost always wrong. Equipment age can span decades. One site runs fully networked lines aligned with Industry 4.0 in manufacturing, while another depends on machinery from 2004 that a veteran crew keeps running through instinct. Labor models mix union and non-union rules. Supplier ecosystems reflect regional logistics and contracts signed years ago. These are not exceptions. They are the norm.

Undocumented Workarounds

Every mature facility accumulates informal fixes that never make it into process documentation. A sensor bypass was installed during peak season and never removed, for example. Or a supervisor who reconciles inventory in Excel because the ERP confirmation takes too long. This knowledge lives with operators. Digital tools, including a manufacturing execution system, fail when they collide with this undocumented logic and have no way to accommodate it.

Why Pilots Fail

The new system flags that sensor bypass as a critical alarm every shift. Operators learn to dismiss it, and the company sees noncompliance. The plant sees headquarters deploying solutions for a factory that does not exist in their building. It is the friction between formal software requirements introduced during MES implementation and the informal adaptations that keep production running.

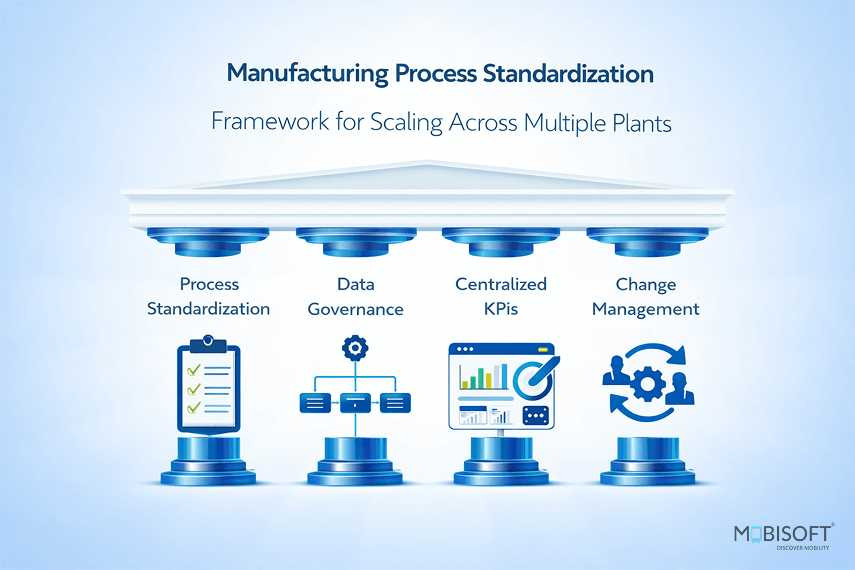

Start With Variation

We believe scaling should begin with a variation audit. Not a software inventory or a network assessment. A structured look at how each plant actually operates within manufacturing operations management. How is downtime defined? Who responds to quality alerts? What thresholds stop production? Which workarounds exist and why? Scaling starts here, not with a deployment timeline.

For deeper insights into sector-specific execution models, explore our Manufacturing Digital Transformation & IT Solutions.

Decision Architecture at Scale

Decision Architecture

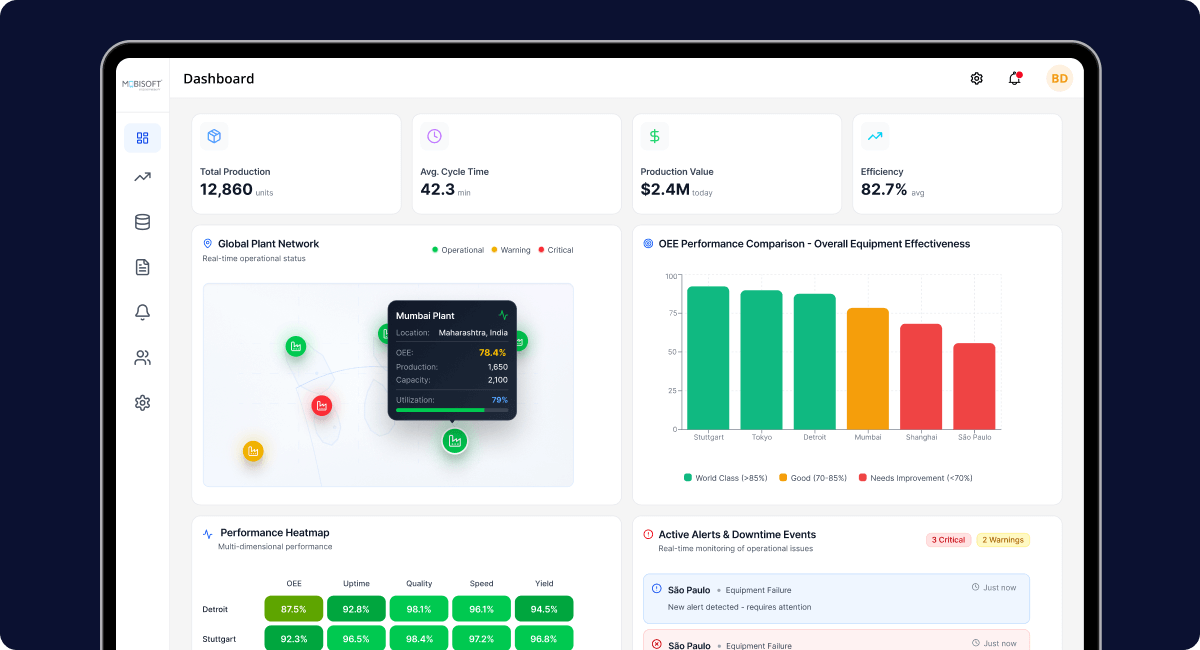

Most manufacturers invest heavily in standardizing software platforms across plants, including manufacturing execution system software. Far fewer invest in standardizing how decisions are made from that software. Two facilities can run identical dashboards with real-time production monitoring and act on them completely differently. One plant escalates a quality deviation within minutes. The other logs it and moves on. The platform is the same, but the decision logic is different.

We believe decision architecture deserves the same discipline as data architecture. Ask:

- Who is authorized to act on which alerts?

- What thresholds trigger escalation versus local correction?

- Which roles are notified during third shift versus daytime hours?

These rules are usually inherited, assumed, or improvised.

Streamline deployment cycles and improve release stability with our DevOps services

Response Playbooks

Enterprise-wide response playbooks close this gap across centralized manufacturing operations. Operational protocols that specify how plants should respond to common events. A downtime event of ten minutes requires notification to plant supervision. Thirty minutes triggers a regional operations review. Sixty minutes reach the VP level. The same logic applies to quality holds, energy spikes, and schedule changes supported by manufacturing analytics.

Digital scale succeeds when reaction patterns are consistent:

- The goal is not identical software configurations.

- Aim for a predictable, disciplined response regardless of which plant the alert originates from.

- This reframes digital manufacturing as a decision-speed problem.

Aligning how people use the new systems under pressure is where durable advantage comes from, especially in ongoing factory digitization efforts.

Managing Data at Network Scale

- Multi-plant digital rollouts flood leadership with metrics. Each site generates dashboards, and the corporation receives competing performance signals that cannot be easily reconciled.

- Plants emphasize different KPIs based on local incentives within multi-plant manufacturing environments. One highlights utilization while the other reports quality. Executives lack clear signals on which problems actually require their attention.

- A tiered metrics model assigns plant teams to hourly execution, regional leaders to weekly patterns, and executives to only the few indicators that predict network instability.

- Signal governance establishes which data points drive intervention versus observation within structured manufacturing operations management. This prevents executive whiplash every time a new plant dashboard goes live.

- Without this discipline, leaders react to whichever plant reports most aggressively. This rewards escalation volume over operational substance.

- The hidden cost is management attention. Time spent reconciling conflicting dashboards is time not spent on constraint removal or capability building.

- Effective tiering also requires retiring old metrics. Most organizations add indicators during rollouts. Few practice the discipline of subtraction.

Understand how enterprise innovation strategies support scalable transformation in our blog on Digital Transformation and Business Innovation.

Phased Digital Expansion Strategy

Risks of Parallel Rollouts

Spreading a digital rollout across five plants at once feels like the fastest route to scale. In practice, it guarantees that no single site receives adequate support. The internal digital team becomes a shared resource stretched so thin that configuration reviews are rushed, training sessions are abbreviated, and the support queue fills faster than anyone can respond during MES implementation.

Human Capacity Limits

The constraint in any multi-plant rollout is not the technology stack, whether it involves manufacturing execution system software or broader cloud manufacturing software, or the vendor implementation hours. It is the small group of people who understand both the digital system and the operational context of each facility. That expertise cannot be cloned overnight. Five parallel deployments simply dilute one team across five incomplete outcomes.

Digital Maturity Gaps

Plants also vary in their readiness for new systems within broader digital transformation in manufacturing efforts. One site may have cycled through three software initiatives in two years and grown cynical about promised improvements. Another may still rely on paper travelers and has never been asked to adopt a digital work instruction tied to a manufacturing execution system. Deploying on the same timeline ignores these differences. The overwhelmed site resents the disruption. The ready site grows impatient with the pace.

Phased Scale Model

A sequenced rollout treats each implementation as intelligence for the next across centralized manufacturing operations. The first site reveals gaps in training materials. The second exposes missing integration points. The third validates the revised approach. It is acceleration through accumulation. The goal is not to finish the deployment calendar fastest. It is to have the entire network operating reliably when the work is done, while effectively scaling manufacturing operations.

See how connected ecosystems are reshaping operational continuity in How IoT Mobile Apps Are Transforming Life & Connectivity.

KPIs That Undermine Scale

- Manufacturing networks are rarely collaborative by design, even within advanced smart manufacturing environments. Plants compete for capital budgets, production volume, and leadership attention. They are measured against each other, then asked to cooperate.

- Local KPIs reinforce this rivalry. A plant rewarded exclusively for utilization or yield gains nothing by sharing process improvements with sister facilities.

- High-performing sites often resist standardization because it erodes differentiation. Being the benchmark confers status and negotiating power. Becoming operationally identical removes both within Industry 4.0 in manufacturing frameworks.

- Budget structures create another layer of friction. The corporation funds the software license for initiatives like multi-plant MES, but the site leaders still control headcount, overtime, and local contractor spend. When digital initiatives consume local resources without budget relief, adoption stalls.

- The plant manager who delays implementation to protect quarterly incentive pay is responding rationally to the compensation design he was given.

- Aligning metrics across the network before scaling is therefore foundational to sustained factory digitization. If collaboration carries zero weight in bonus calculations, collaboration will not materialize at scale.

- Reward cross-site adoption explicitly. Public recognition for plants that successfully implement solutions developed elsewhere signals what leadership actually values beyond production numbers.

- This requires auditing existing incentive structures. The question is simple: do current rewards encourage network performance or silently undermine it?

Discover how intelligent visibility strengthens cross-plant coordination in Future of Smart Asset Tracking: From Visibility to Intelligence.

From Digital Projects to Network Discipline

Multi-plant performance is a systems discipline across multi-plant manufacturing environments. It demands clarity on how variation is interpreted, how signals are filtered, and how authority travels across sites within multi-site manufacturing operations. Leaders who treat operational differences as data, rather than an inconvenience, will design networks that adapt without fragmenting during broader digital transformation in manufacturing efforts. Those who sequence expansion according to learning velocity, not corporate urgency, will compound capability instead of compounding friction.

The mandate is precise. Map reality before enforcing uniformity. Codify response logic before amplifying alerts. Protect management attention as a strategic resource. Align incentives so plants advance collective strength alongside local output.

When facilities operate with shared judgment and calibrated autonomy, digital manufacturing becomes a structural advantage. Coordination, practiced deliberately, will define industrial leadership.

Learn how connected systems reduce operational blind spots with our Expert IoT Development Services.

Key Takeaways

- Multi-plant digital scale fails when operational variation is ignored, and software such as a manufacturing execution system is deployed onto inconsistent processes without prior alignment.

- A structured variation audit reveals hidden workarounds, decision gaps, and informal routines that determine whether systems stabilize or fragment.

- Standardizing decision thresholds and escalation logic matters more than forcing identical software configurations across facilities.

- Executive attention must be protected through tiered metrics, with predictive indicators elevated and redundant dashboards retired.

- Rollout sequencing should follow plant absorption capacity and learning velocity, not corporate deployment calendars.

- Incentive structures must reward network contribution, or local optimization will quietly undermine enterprise coherence.

- Sustainable scale emerges when plants operate with calibrated autonomy inside shared operational guardrails.

Frequently Asked Questions

How do you prevent digital maturity gaps from widening between plants over time?

Scaling often accelerates disparity instead of reducing it. High-performing sites adopt enhancements quickly while slower plants fall further behind. Leaders should establish rotational deployment teams and shared performance reviews so knowledge circulates deliberately, preventing digital capability from clustering in only a few flagship facilities.

What financial structure supports multi-plant digital expansion sustainably?

Central funding alone distorts accountability, while fully local funding slows adoption. A blended investment model works better, enterprise capital for core platforms, plant-level budgets for configuration and adoption. This balance preserves ownership without burdening sites with costs they cannot influence directly.

How can manufacturers prevent data from becoming politically manipulated across sites?

When plant comparisons influence capital allocation, metrics become strategic weapons. Clear calculation standards, third-party validation rules, and automated data pipelines reduce interpretive flexibility. Transparency in how performance is derived protects credibility and discourages selective reporting designed to secure an advantage.

When does cross-plant standardization begin to reduce innovation?

Standardization becomes restrictive when it freezes experimentation. A defined sandbox policy allows plants to trial process improvements within guardrails, then formalize proven changes across the network. Discipline should enable replication of success, not suppress localized ingenuity.

How should leadership manage digital fatigue during multi-year rollouts?

Fatigue emerges when initiatives overlap without a visible payoff. Sequencing must include stabilization periods where teams operate new systems without additional disruption. Publicly tracking adoption milestones and demonstrating operational gains reinforces credibility and sustains engagement beyond initial launch phases.

What distinguishes synchronized networks from merely connected plants?

Connectivity shares data. Synchronization aligns interpretation and response. In synchronized networks, escalation logic, intervention timing, and accountability pathways are predefined across facilities. This consistency allows local autonomy within shared boundaries, creating coordinated action rather than parallel, disconnected optimization.

February 20, 2026

February 20, 2026