The traditional image of a golf cart is now obsolete in modern operations. What we are witnessing is a functional reassignment of the vehicle, from a leisure accessory to a deliberate operational asset. For managers of campuses, industrial parks, and large facilities, this represents a tangible opportunity. The core appeal lies in addressing a universal operational challenge: efficient, quiet, and clean intra-facility transportation. This transition is not about adopting a novelty. It is about recognizing a mature tool specifically suited to the scale and pace of contained environments. The following analysis details how this asset class integrates into operational strategy, delivering measurable gains in productivity, cost management, and sustainability.

The Operational Evolution of Golf Carts in Facilities

Let us clear the air, so to speak. The golf cart’s most important journey did not happen on a golf course. It happened when it left the green and rolled onto the concrete, asphalt, and pathways of working facilities. That is where its story truly began. For managers, this transition is not a minor detail, but the entire point. Understanding this evolution helps us see the vehicle not as a toy but as legitimate operational equipment. Its history reveals a natural fit for the challenges you manage every day.

A History of Utility in Internal Mobility

The first carts answered a basic need on the golf course for carrying clubs quietly. That early electric motor was a fortunate choice. It meant no smoke, no loud engine, just a faint hum. This trait did not go unnoticed for long. Facilities with large indoor spaces or noise-sensitive environments saw potential. A warehouse manager might have thought, Why start a loud truck to cross the building? A hospital groundskeeper needed a quiet way to move. The vehicle slipped into these roles almost by accident. It proved itself through sheer practicality, one silent trip at a time.

Smart Internal Mobility Solutions for Facilities

So what makes it fit so well? Think about movement within your facility:

- It is often a series of short, disconnected trips. A technician going for parts or a supervisor doing rounds, for instance.

- Using a full-sized vehicle for this is wasteful. It burns fuel idling and is hard to park in tight spaces.

- A small electric golf cart solves this neatly. It turns a long walk into a quick ride, saving precious minutes that add up across a team.

- The logic is compelling. It is about using the right tool for the job, and for internal mobility solutions, the scale is just right.

Sector-Specific Adoption of Commercial Golf Carts

Different industries have shaped this tool to their own needs:

- Airports use utility vehicles for facilities to navigate tight spaces between gates and on tarmacs. University campuses rely on campus mobility vehicles for security patrols and maintenance crews.

- In large resorts, they become the bloodstream of guest service and operations. Each application shares a common thread.

- The vehicle solves a specific internal logistics problem. It is not about public transit.

- It is about optimizing movement on private property. This practical adoption is the strongest testament to its utility.

Compliance Priorities and ESG Integration

For you, the regulatory focus is different:

- It is less about city street laws and more about workplace safety and corporate policy. Internal compliance standards often guide their use.

- More importantly, the global push toward sustainability is now a boardroom issue. Electrifying your ground fleet with electric utility vehicles is a clear, visible step toward ESG goals.

- It can lower your operational carbon footprint in a reportable way. This aligns environmental responsibility with operational planning.

- It turns a simple vehicle swap into part of a larger, strategic objective.

To enhance visibility and control across all utility vehicles, consider integrating advanced fleet management software solutions that centralize tracking, maintenance, and utilization insights.

Technology Tailored for the Worksite

For a facility manager, technology is not about flashy features. It is about solving problems. The modern worksite mobility vehicles embody this principle. Its advancements are carefully engineered to meet specific operational demands: reliability, oversight, and safety. This is where the vehicle truly earns its place as a professional asset, not a recreational holdover.

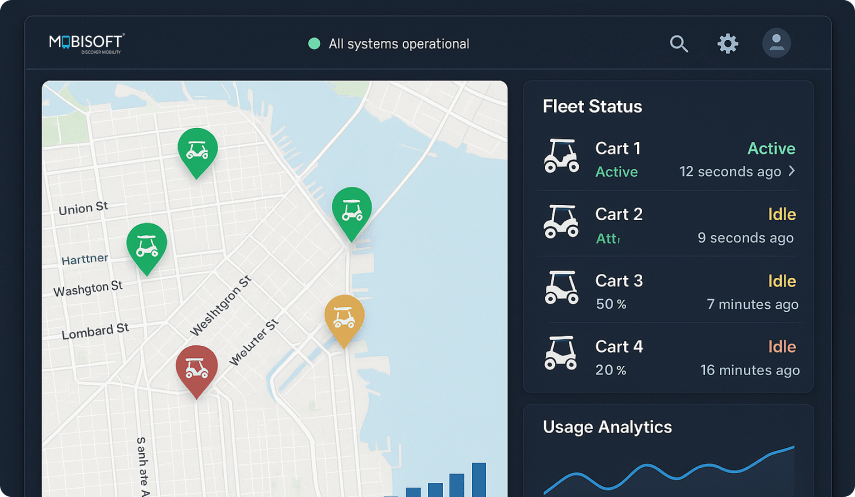

Intelligent Fleet Connectivity

Consider the challenge of managing a dispersed fleet. Where is each vehicle? Is it being used effectively?

- Modern systems provide the answer. Integrated telematics and GPS convert each cart into a visible data point on a manager's dashboard.

- You can see their real-time location, which optimizes dispatch and enhances asset security.

- You can analyze usage patterns to right-size your fleet, eliminating unnecessary capital spend.

- This connectivity turns a simple transport tool into a source of operational intelligence. It provides the clarity needed to make smarter, more efficient decisions for golf cart fleet management.

Reliable Power Output

The core of any electric golf cart is its battery:

- Here, the transition to lithium-ion technology is a game-changer for daily operations. For you, the benefits are measured in uptime and predictability.

- These batteries charge significantly faster than older types, reducing downtime between changes. They last for more charge cycles, which lowers long-term replacement costs.

- Critically, they provide consistent power output throughout their charge. This means the vehicle performs the same at the beginning and end of a long change.

- That reliability is what allows you to schedule tasks with confidence, removing a common point of operational uncertainty.

Configuration Over Customization

In a facility, personal taste matters less than practical function. The real advantage lies in configurable designs:

- Think of the vehicle as a flexible platform. For example, a maintenance team might need a model with a utility bed and tool racks.

- The ability to specify these configurations upfront ensures the tool perfectly matches the task. This approach streamlines your procurement and maintenance.

- It moves the conversation away from colors and accessories and toward ergonomics, payload, and specific job requirements.

- It is a more professional, results-oriented way to build a fleet of commercial golf carts.

Safety-First Design for Facility Transportation

Operating in shared spaces demands proactive safety, and modern vehicle design reflects this priority:

- Features like electronic stability control help maintain control during turns, especially when carrying a load.

- Speed can be precisely programmed and limited for different zones within your facility, a crucial control for pedestrian areas.

- Advanced lighting and braking systems ensure the vehicle is seen and can stop effectively.

- These are not optional extras. They are fundamental engineering responses to the real-world conditions of a busy facility.

- They protect your staff, your visitors, and your liability profile, making the integration of these facility transportation solutions a responsible, manageable decision.

To explore how mobile-led digitization is reshaping day-to-day fleet control, you can refer to Smart Fleet Management via Mobile Apps.

The Compelling Economic Case for Facility Managers

For any operational upgrade, the final question is always financial. Does the investment make sense? With modern worksite mobility vehicles, the economics have become unexpectedly clear. The narrative changes from simple purchase price to a broader, more persuasive story about total cost, productivity, and strategic value. This is where the conversation moves from the garage to the boardroom, grounded in tangible returns.

Cost of Ownership

The initial price tag is just one piece of the puzzle. A true financial analysis looks at the entire lifecycle of the asset. This is where electric utility vehicles build a strong case. Their energy costs are markedly lower than fuel for gas carts. Electricity is simply cheaper per mile than gasoline, and this difference compounds over thousands of operational hours.

Maintenance presents another significant saving. Oil, spark plugs, or a complex transmission are missing, for example. Therefore, maintenance intervals are longer, requiring no complex work. This reduces both inventories and labor hours for your maintenance staff. When you calculate the savings in energy and upkeep over a five to seven-year lifespan, the higher upfront cost is frequently absorbed, leading to a lower total investment.

The Productivity Dividend

Economics is not just about reducing costs. They are also about enhancing output. This is the productivity dividend. These vehicles recover what is often the most wasted resource in a large facility: time. Consider a technician walking fifteen minutes to a remote site for a repair. With a golf cart for facilities, that trip takes three minutes. That is twelve minutes saved, per trip, that can be applied to skilled work.

For security, it means more ground can be covered per change, increasing visible presence and response capability. This rescues man-hours from transit and reallocates them to value-added tasks.

Data for Smarter Use

The connectivity discussed earlier does more than track location. It generates the data needed for intelligent fiscal management. With accurate reports on vehicle utilization, you can answer critical questions. Do we have too many vehicles sitting idle? Do certain departments need dedicated assets? This data allows you to right-size your golf cart fleet management, preventing capital from being tied up in underused equipment. It also enables predictive maintenance, scheduling service based on actual use rather than a calendar, which prevents costly breakdowns and extends asset life. This turns facility transportation solutions from a guessing game into a precise, strategic function that directly protects your investment.

Current Market Pulse

The market itself validates this change. Growth in the commercial and utility segment is robust. This increasing demand from sectors like hospitality, logistics, and security is driving manufacturers to prioritize durability and features that matter in professional settings. You are not buying a consumer product adapted for work.

You are increasingly able to specify a tool engineered for it. This competition elevates quality and focuses innovation on operational needs like payload capacity, corrosion-resistant frames, and software integration for industrial mobility vehicles.

If your operations also extend to high-traffic environments or organized events, adopting specialized event transportation software solutions can further streamline movement, improve safety coordination, and support on-ground logistics.

Sustainability as an Operational Advantage

Sustainability often feels like a separate goal, a box to check for corporate reports. In the context of facility operations, however, it is something more direct. It is a source of operational advantage. The integration of an electric golf cart fleet turns environmental responsibility into a tool for efficiency, cost control, and positive branding. This is where doing good and doing well become the same thing.

Meeting ESG Goals

Many organizations now have formal Environmental, Social, and Governance (ESG) commitments. For a facility manager, these can seem abstract. An electric fleet provides a concrete, measurable action. Replacing gasoline-powered utility vehicles for facilities directly reduces your facility's Scope 1 emissions. These are the greenhouse gases you produce directly. This reduction is not an estimate.

It is a calculable metric you can report. It demonstrates tangible progress to leadership and stakeholders. This turns an operational decision into a strategic contribution, aligning daily ground logistics with the organization's public commitments and often, its access to green financing or incentives.

The Full Lifecycle View

True sustainability looks beyond the tailpipe. It considers the entire life of the equipment. Responsible manufacturers now design with this in mind. The use of recycled plastics in body panels or sustainably sourced fabrics for seats is becoming more common. This matters for your own procurement policies. It allows you to support a circular economy, reducing the environmental impact from the very creation of the assets you use.

Renewable Integration On-Site

The sustainability story extends to energy sourcing. A fleet must charge, and that power has a footprint. The most forward-thinking facilities are combining their facility mobility solutions with on-site renewable generation. Solar panel canopies over parking or charging stations are a prime example.

This setup allows you to power your mobility operations directly from the sun. It reduces demand on the grid, can lower energy costs over time, and provides a powerful visual symbol of your commitment. It converts idle space like a maintenance yard roof into an active energy asset. This integration creates a cohesive system where your vehicles are not just low-speed electric vehicles, but are powered by clean energy you control.

Low Noise Advantage

The benefit of zero emissions is clear for air quality. The value of near-silent operation is equally important, though less discussed. In many facilities, noise is a form of pollution. It affects concentration in office campuses, the healing environment in hospitals, and the guest experience in resorts. An electric golf cart fleet virtually eliminates noise pollution from ground operations. This improves the quality of the environment you manage. It demonstrates consideration for the well-being of everyone in that space.

For facilities accelerating their clean mobility initiatives, modern electric vehicle fleet solutions offer a practical pathway to lower emissions and operational energy costs.

Seamless Integration into Daily Operational Flow

Adopting a new tool is one thing. Weaving it seamlessly into the daily rhythm of your facility is another. Success here does not come from the vehicle alone. It comes from thoughtful integration. This means considering workflows, infrastructure, and people. The goal is to make the vehicle feel less like a new addition and more like a natural, indispensable part of how your facility operates.

Bridging Daily Distances

Every large facility has its own version of a last-mile problem. It is the gap between two operational points. Perhaps it is the distance from the central tool crib to a remote maintenance site. Maybe it is the journey from a delivery bay to a specific storage area. These short, frequent trips are where efficiency is lost. A strategically deployed internal mobility solution bridges these gaps. It collapses distance and time. For example, a cart dedicated to the grounds crew can carry mulch, plants, and tools directly to the point of work, eliminating multiple back-and-forth trips.

Enhancing Safety Protocols

The quiet, agile nature of these vehicles makes them exceptional partners for safety and security teams. Their zero emissions allow them to operate indoors in parking structures or warehouses without air quality concerns. Security can conduct subtle, observant patrols without the announcement of a rumbling engine. For emergency response, they can quickly transport personnel and first-aid equipment across crowded events or expansive campuses. Their small size allows them to navigate through crowded spaces where traditional vehicles cannot go. Integrating campus security vehicles into these protocols is a force multiplier.

Backbone for the Fleet

The vehicles cannot operate in a vacuum. Their successful adoption depends on supportive infrastructure, which requires forethought. The primary consideration is charging. A structured plan is essential. Will you use centralized charging stations in a maintenance yard, or distribute smaller charging points near key operational hubs? Assessing daily mileage and duty cycles will determine your electrical needs. It is wise to involve your facilities or electrical team early. They can ensure your power supply is adequate and that installations are safe and up to code. This planning also includes considering physical storage for a secure, accessible home base.

Designing for Mobility

The most forward-thinking approach is to design the facility itself around efficient, low-impact mobility. For new construction or major renovations, this means considering facility transportation solutions pathways alongside pedestrian walkways and traditional roads. It might involve specifying slightly wider corridors in warehouses or covered pathways between buildings. For existing facilities, it involves auditing traffic flow. Can you designate specific low-speed lanes? Are there choke points that need to be addressed? This proactive design philosophy makes the safe and efficient use of internal logistics vehicles the default, not an afterthought. It signals a commitment to a fluid, adaptable, and thoughtful operational environment where every movement is considered.

You can also explore how industry leaders embrace digital tools in transporter workflows through insights shared in Technology in Transporter Operations.

The Future of the Smart Facility Fleet

Looking ahead can feel speculative. In the realm of facility operations, however, the future is being built on very practical foundations. The trajectory for facility mobility solutions points toward greater integration, intelligence, and indispensability. This is not about far-off concepts. It is about the next logical steps in a tool becoming a seamless part of your operational intelligence.

Autonomy in Predictable Environments

The idea of self-driving vehicles often brings to mind public roads. The more immediate future lies within the controlled confines of private facilities:

- Imagine a vehicle that completes a pre-programmed security loop overnight, or one that navigates a warehouse aisle to deliver parts to a workstation.

- This is not science fiction. It is a natural extension of existing GPS and sensor technology. In a closed, predictable environment, autonomous functionality can handle repetitive, time-consuming tasks.

- It frees your personnel for more complex work that requires human judgment. This future is about leveraging consistency to boost efficiency.

Predictive Maintenance and AI Diagnostics

Reactive maintenance is a cost. Scheduled maintenance is an improvement. Predictive maintenance, however, is the goal:

- Future systems will move beyond simple usage tracking. They will analyze performance data to forecast potential issues before they occur.

- A slight change in motor vibration, a trend in battery charge times, these subtle signs can be flagged by intelligent diagnostics.

- This means you could receive an alert to service a golf cart fleet management vehicle next week, avoiding a breakdown during a critical change. It transitions maintenance from a calendar-based chore to a precise, data-driven prescription.

- This saves money, extends asset life, and above all, protects operational continuity.

Modular and Adaptable Platforms

The need for flexibility will only grow. Future fleet design will likely emphasize modularity even more strongly:

- Think of a standard vehicle chassis as a blank slate. Different modules could be attached for different changes.

- A flatbed for materials handling in the morning, a personnel carrier for changing in the afternoon, or a tool locker for the evening maintenance crew.

- This approach maximizes the utility of each physical asset. It reduces the total number of vehicles you need to own and store, especially if you have varying daily needs.

- This adaptability turns the fleet into a dynamic resource that can be reconfigured as quickly as operational demands change.

Reputation Through Action

Finally, we must consider the broader message. The tools you choose signal your priorities:

- A modern, smart, and clean fleet does more than perform tasks. It projects an image of operational excellence.

- It shows visitors, clients, and employees that you value innovation, safety, and sustainable mobility solutions. This enhances your facility's brand and can even aid in recruitment.

- People want to work in forward-thinking environments. Your choice in operational assets quietly communicates that you are building one.

- The future, therefore, is not just about what these vehicles do. It is about what they say about your entire operation.

For deeper visibility into real-time movement, location data, and route behavior, a modern Fleet Tracking App Solution can add measurable operational clarity.

Redefine Your Ground Mobility

The role of golf carts for facilities is now clearly defined within professional facility management. This evolution represents more than a simple change in where the vehicle drives. It signifies a deeper recognition of intelligent tool selection.

The core argument is practical, not theoretical. Modern utility vehicles for facilities offer a tangible solution to the universal challenges of intra-facility transportation. They deliver proven gains in staff productivity, operational cost reduction, and measurable sustainability. The technology now supports rigorous daily use, and the economics firmly justify the investment.

Ultimately, this is about operational clarity. It is about choosing the right instrument for a specific task. For moving people and equipment across the private grounds of a campus, airport, or industrial site, these vehicles are the instrument. They bring a quiet efficiency to the forefront of daily operations.

The opportunity is present and actionable. It invites a reassessment of long-standing habits. By integrating these assets, you are not merely purchasing equipment. You are investing in a more fluid, responsible, and efficient operational model. The path toward a smarter facility begins with these deliberate, grounded choices.

Key Takeaways: Facility Mobility Solutions

- The fundamental paradigm change is viewing these as operational assets. Their value is measured by efficiency, cost, and sustainability within your facility's ecosystem, reinforcing facility mobility solutions.

- Modern advancements provide dependable performance, actionable data, and enhanced safety, transforming utility into managed intelligence.

- The economic case wins on total cost, not price. It is built through lower energy/maintenance spending and the recovered productivity of your team, making it a logical investment for commercial golf carts.

- True sustainability is operational. Electrifying your fleet delivers reportable emission reductions and aligns corporate environmental goals with daily, on-the-ground practice, enhancing sustainable mobility solutions.

- Integration separates simple use from real value. This includes matching worksite mobility vehicles to tasks, establishing protocols, and building supportive infrastructure into workflows.

- The future points toward deeper embeddedness, evolving into modular and data-aware components.

- Building these assets and managing them effectively will become integral to operational resilience and internal mobility solutions in smart facility planning.

FAQs

What are the real hidden costs when switching from gas to electric for our fleet?

Look beyond the purchase price. The true savings emerge in ongoing operations. You eliminate fuel purchases, oil changes, and complex engine maintenance. Budget instead for a dedicated charging infrastructure and possible electrical upgrades. The long-term financial advantage is clear, but it requires a redirection in how you categorize mobility expenses from consumable fuel to managed utilities using electric utility vehicles.

How do we ensure safety when these vehicles mix with pedestrian traffic on site?

Protocol is as important as the hardware. Establish strict speed limits for different zones, enforced by electronic governors on the vehicles. Mandate clear regulations and operator training. The vehicles themselves should have automotive-style lights, horns, and mirrors. Success depends on combining safe technology with a culture of shared awareness on your pathways using internal logistics vehicles.

Are there specific regulations for using these as official work vehicles on private property?

While public road rules may not apply, workplace safety regulations certainly do. In the U.S., OSHA guidelines for low-speed electric vehicles in workplaces are key. Your own insurance carrier will also have requirements. It is less about a driver's license and more about internal certification, operator training, and meeting defined equipment safety standards for your industry.

What's the first step in planning the charging infrastructure for a new fleet?

Begin with a simple audit. Track the daily mileage of your current gas units. This data reveals your total energy demand. Then, consult with your facilities team to map central, secure locations where vehicles naturally park for extended periods. The goal is to install sufficient charging where the fleet already rests, not to redesign your operational flow for facility transportation solutions.

Can these vehicles genuinely withstand harsh industrial or all-weather environments?

Yes, provided you specify commercial-grade models. Look for rust-resistant aluminum frames, sealed electronics, and heavy-duty suspension. For cold climates, insulated battery packs and enclosed cabs are available. The key is procuring vehicles engineered as industrial mobility vehicles, not consumer leisure products. Their durability is a matter of specification, not chance.

How does the data from a connected fleet actually inform managerial decisions?

It converts observation into evidence. Utilization reports show you if you have too many or too few vehicles, preventing wasted capital. Maintenance alerts based on actual use prevent costly downtime. Route data can reveal inefficient workflows. This intelligence allows you to manage a fleet as a dynamic asset, optimizing it for both performance and cost through golf cart fleet management.

December 9, 2025

December 9, 2025